Advantages of Leather Laser Engraver

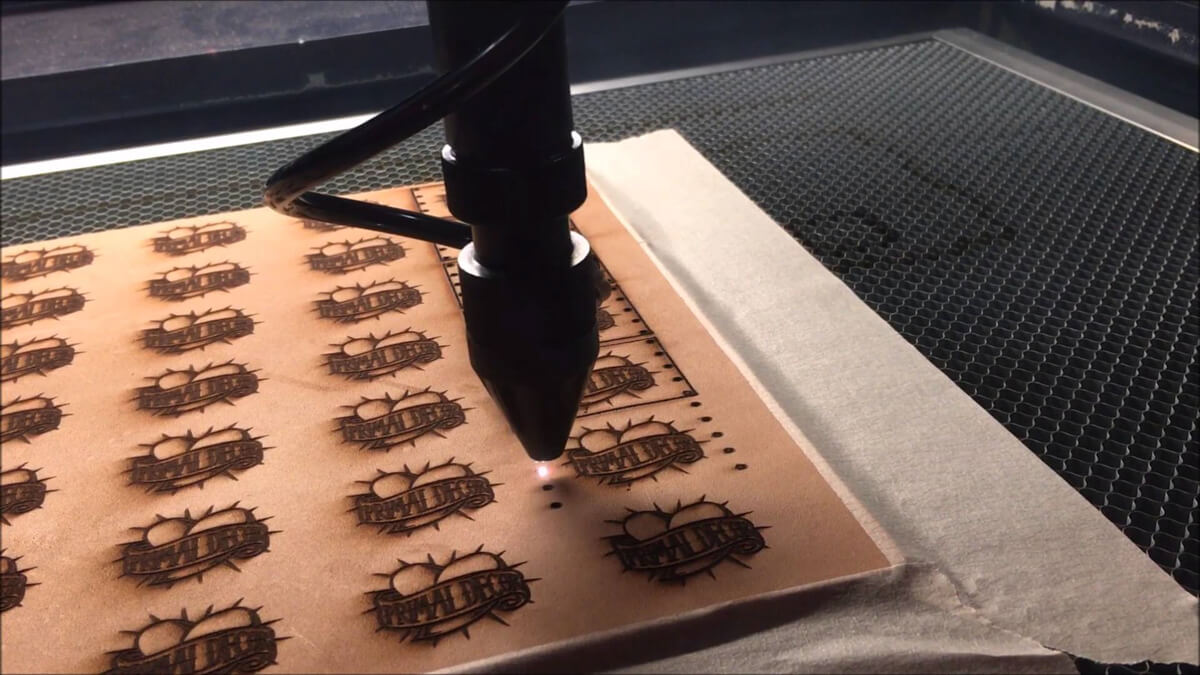

The main advantage of using a laser to engrave leather is that you can engrave without destroying the surface of all materials, giving you more design freedom compared to other processes. Other advantages are:

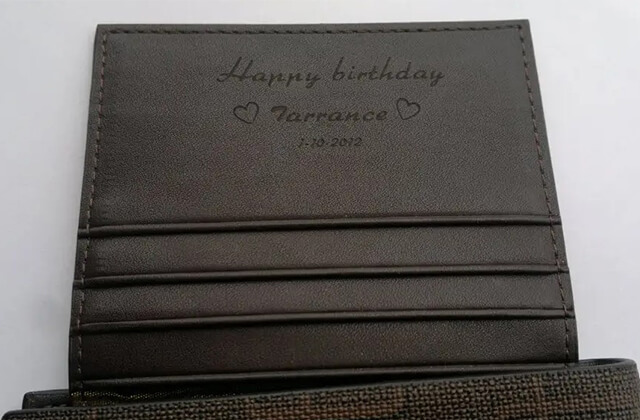

High precision, very fine details can be engraved.

There is no contact with the leather surface, which means there is no risk of damage to the leather.

Minimal heat from the laser beam will not cause any damage or discoloration to the leather in non-engraved areas.

The leather is highlighted with high contrast, resulting in a natural look.

Since the laser burns the leather surface, it is durable and indelible.

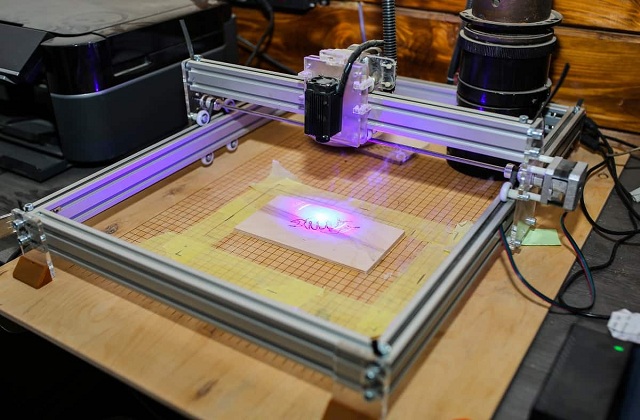

The operation is fast and convenient, and it is very suitable for small-scale production.

Laser Engraving Tips on Leather

The main thing to remember when laser engraving leather is that the laser needs to have good contact with the leather surface to produce a clean, sharp image. Without good contact, lasers can produce dirty, smoky images.

Leather also absorbs moisture easily and becomes slippery when wet. This makes it difficult to hold in place when engraving, and can also cause the engraved image to fade over time.

To address these issues, it is important to use the correct type of leather and adjust the laser settings accordingly.

If you're using a standard desktop laser engraver, it's best to use a thicker grade of leather that has been treated with a surface treatment such as sealant or varnish. This will help prevent fading of the image and ensure good contact between the leather and the laser.

If you are using a high powered industrial laser engraving machine, thinner grades of leather can be engraved without any surface preparation. However, you will need to adjust the engraving settings to take into account the natural water absorption of the leather.

In general, slower speeds and lower power settings should be used when engraving leather. The laser should be set to "Mark" mode instead of "Cut" mode, and the focus should be adjusted so that the beam just touches the leather surface.

By following these tips, you can create beautifully sculpted images on leather that will last for years.