Engraving leather is not as popular as metal engraving, but this is probably because most people think of embossing rather than leather engraving when dealing with leather. However, laser engraving and laser cutting are particularly suited to versatile materials like leather. This natural, hard-wearing, durable material has been used for thousands of years, but with the help of laser processing, there are entirely new possibilities for improving this material. In this article, you will find everything you should know if you want to have leather laser processing.

If you want to engrave your own leather products, you can start by buying a laser engraver to take home. Desktop desktop laser engraver is very popular nowadays, they are small and don't take up much space, and they are not expensive, yet you can realize your creations and even make money with them! By the way, Sculpfun is very cost-effective and powerful, for example, Sculpfun S10, these two laser engraving machines are one 10W, the other 20W, you can choose according to your needs.

Lasering Applications For Leather

When we talk about leather lasers, we always refer to two types of leather processing: laser engraving and laser cutting. The combination of the two produces very different possible applications.

Laser engraving on leather is an excellent way to personalize almost any leather product. In addition to natural leather and even hides, there are many artificial leather types for which laser processing applications for leather are also suitable for laser engraving and laser cutting. Sculpfun S30 Pro Max, also a 20W laser engraver and the latest machine currently available from sculpfun, is so powerful that some materials other engravers need multiple cuts to complete, while this machine Once is enough, which greatly improves the engraving efficiency.

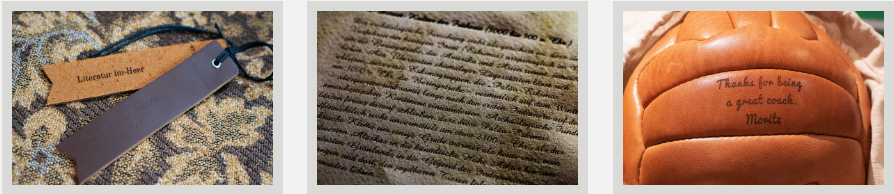

Whether you want to laser engrave logos or complex graphics on the leather or write on the leather, it can be executed. Therefore, the ways in which laser engraving can be used are the following

- Briefcases

- Folders

- Notebooks

- Pencil cases

- Leather bags

- Bracelets

- Belts

- Shoes

- Even sporting goods

The most diverse leather products of everyday life can be personalized.On the HPTOW website, for example, we offer particularly high-quality laser engravers from various brands.

In combination with laser cutting, this leather engraving can also be used to cost-effectively produce accessories, shoes, decorative items, or cut leather parts for making leather labels.With laser cutting, even filigree patterns can be cut very precisely.

Please note that laser engraving and laser cutting can alter the surface of the leather and the natural protective features of the leather may be lost as a result. Engraved leather may absorb water when cleaned, and high-contrast engraving will disappear over time. In this regard, laser engraving of leather is only applicable to a limited extent for making labels for clothing or other items that come into frequent contact with water.

How Laser Cutting And Laser Engraving Of Leather Works

When a laser cuts leather, the laser beam causes a temperature rise in the material's cut seam that exceeds the leather's sublimation temperature. As a result the evaporated leather escapes as smoke and dissipates the introduced heat. As a result, the surrounding material is only slightly stressed by the heat, which, depending on the type and thickness of the leather, may result in a slight discoloration of the cut edge. When laser cutting leather, the cut edges are immediately sealed and therefore no abrasion occurs. Laser cutting of leather is completely contact-free. This way, there are no pressure points on the leather and even complex leather patterns can be cut in a very short period of time.

When engraving leather, the top layer of the material is removed. Depending on the color, pre-treatment and type of leather, the result is a dark engraving.

Advantages When Engraving And Cutting Leather With Laser

- Fast, simple and contactless processing of ready-made products

- Precise pattern engraving even on large areas

- Precise, clean cuts

- No abrasion during cutting due to sealed cutting edges

- Material-friendly, non-contact processing, so no pressure points

- More durable than printing

- Standard items can be personalized quickly and easily

By the way: Sculpfun S9 can engrave all kinds of materials; wood, paper, cardboard, plastic, white, PCB board, aluminum oxide, 304 Stainless steel, ceramic, dark stone etc. Although only 5W power Although it only has 5W power, it can still handle cutting procedures.

.jpg)