This is a question asked by many users, they want to know what is the main difference between fiber laser engraving machines and MOPA laser engraving machines, just color engraving on certain materials. Why is the price of MOPA laser engraving and cutting machine more expensive? What materials can these techniques engrave? Now all these questions will finally be answered in this blog on MOPA and fiber lasers.

Different Internal Technologies

Even though the two machines look very similar or identical, on the inside, they work differently. Fiber lasers use a technique called Q-switched, which allows the power supply to produce only path light between 1 and 500 kHz.

The other best-known master oscillator power amplifier, MOPA, generates power in a different way, which allows the machine to pulse at much higher amplitudes than fiber optics, from 1 to 4000 kHz. These allow MOPA lasers to engrave differently on certain plastic and metal materials than Q-switched or fiber laser techniques. MOPA laser engraving machine is used in a relatively wider range, and it will be used in more places.

MOPA laser engraving machine, MOPA laser engraving, metal color marking, metal color marking, laser metal engraving, mainly used in metal engraving and metal cutting, because MOPA has greater power and ability to cut thicker materials.

Fiber Laser Technology

What is the difference between UV laser, laser engraving machine, UV laser engraving machine, UV laser engraving, fiber laser engraving?

| What materials can these machines engrave? MOPA Laser |

Fiber laser or Q-switched This machine can engrave: |

| This machine can engrave: | Gold |

| Aluminum (also available in dark color) | Aluminum |

| Stainless Steel (Multiple Colors) | Stainless Steel (white and dark colors only) |

| Brass | Platinum |

| Platinum | Silver |

| Silver | Titanium |

| Titanium | Brass |

| Tungsten | Tungsten |

| Carbide | Carbide |

| Nickel | Nickel |

| Carbon steel | Carbon steel |

| Crom | Crom |

| Copper | Copper |

| Iron and other metals | Iron and other metals |

| ABS plastic (low melting rate) | ABS plastic (high melting rate) |

| PC plastic (low melting rate) | PC plastic (high melting rate) |

| PLA plastic | PLA plastic |

| Silicon plastic | Silicon plastic |

| PBT plastic, etc. | PBT plastic, etc. |

These machines can engrave different plastics, but in some of them, you will feel the engraving with the touch of your finger.

MOPA Laser is Still in Development

The technology isn't new, but it's still a long way from the high-speed engraving that fiber lasers can achieve. Color engraving with an actual MOPA laser isn't fast, and if you're looking to engrave thousands of metal pieces with colorful logos every day, this is what you should expect. The truth is that color engraving is not fast, it can be slow, depending on the mark you choose and the number of colors you want to engrave.

On the other hand, fiber lasers or Q-switch machines have better engraving speeds on some plastics and metal materials. Relatively, the laser power currently used is also smaller, especially the power used in household fiber laser engraving machines is relatively small.

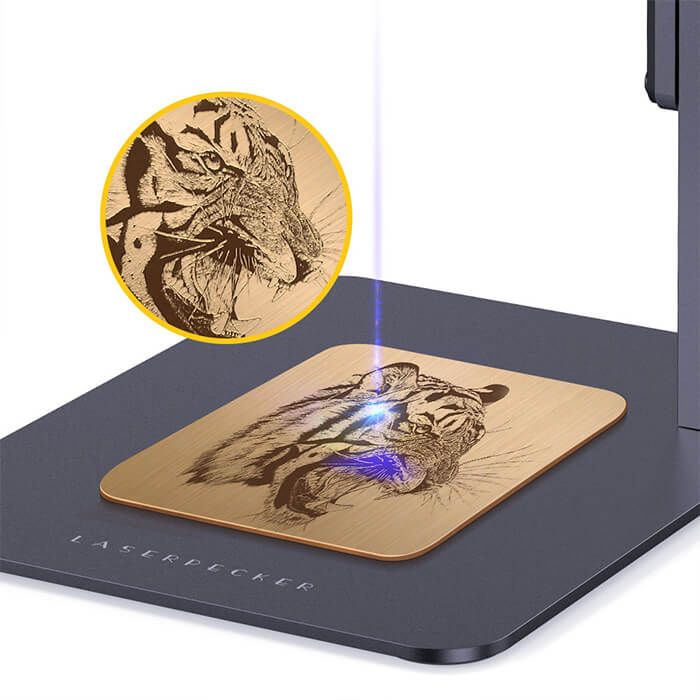

For example, I used LaserPecker 2 to engrave logos. Its engraving speed is very fast, and it can fulfill the requirements I need very well. I have also sold products with logos in online stores, which can help my business very well. , but when I need to cut the material the LaserPecker 2 takes longer to cut, so I later re-purchased an Ortur Laser Master 3 for cutting the material, and now it can handle what I need to cut Material.

A recommendation:

If you are also using a fiber laser engraving machine, if you just want to do an engraving and make your items more personalized, then you can choose a machine with a laser output power of 5W, such as the LaserPecker 2 I am using now, which is very good but also supports scroll engraving, no longer limited by the material size

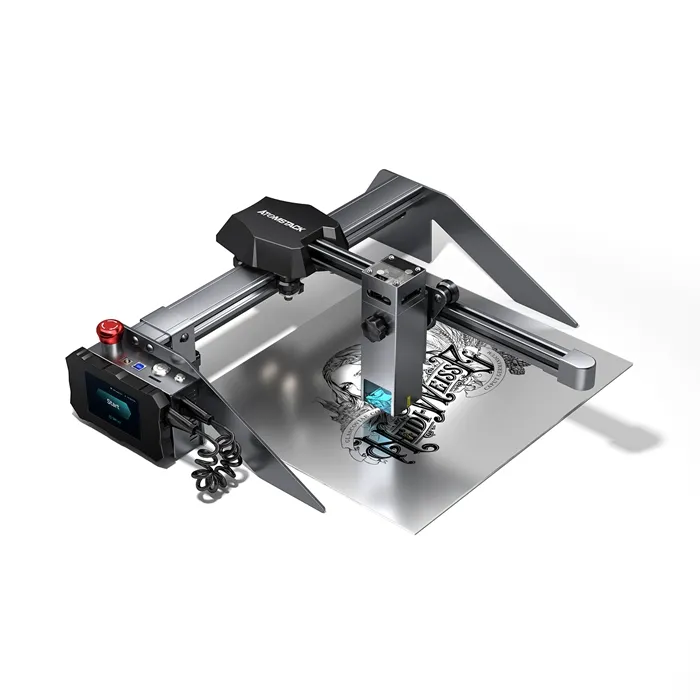

But if you want to achieve the cutting effect, then I suggest you choose a laser engraving and cutting machine with a laser output power of more than 10W, and the higher the laser output power, the faster your cutting speed will be, xTool D1 Pro and Ortur Laser Master 3 They are all good choices, I just chose a 20W or more, which is convenient for my more laser cutting needs.

In conclusion, both machines can do similar jobs, however, if you are looking for a better finish on plastic materials and the possibility to engrave different colors on stainless steel, titanium or aluminum, you might consider the MOPA laser's Solutions can be provided. On the other hand, if you just want to engrave metal at high speed and depth, and don't need to engrave color on the metal, then you can choose a fiber laser. These machines may look the same, but they differ not only in how well they work and in technology but also in price, MOPA laser technology also tends to be more expensive than regular fiber Q-switched lasers.