Laser Engraved Glass

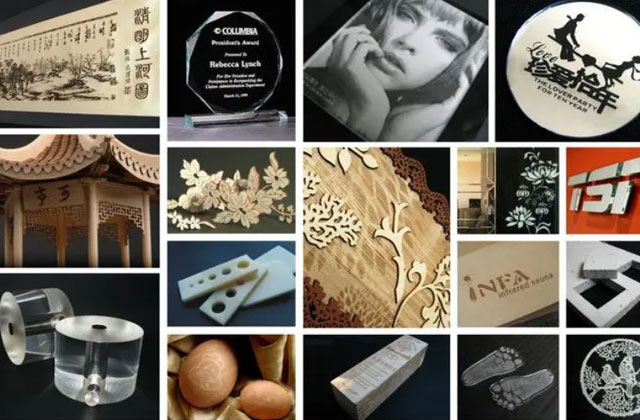

Laser marking glass is quick, easy, and clean, and requires no masks, film, or water. Most importantly, it does not require clamping the product as there is no physical contact with the product being engraved. Laser cutting is possible if it can be positioned correctly. Laser glass can contain almost anything you can generate on a computer screen. Text, photos and artwork can all be laser engraved. Lasers are particularly good at creating highly detailed artwork—art that is too intricate for a mask, or on products with complex surfaces that don’t allow the application of a mask.

Etching glass with a laser is an art. As different glass types test different glass types with different speed and power settings.

Applying a damp tissue to the engraved area of the glass will help reduce chipping and give you a smooth, frosted look.

When laser etching the mirror, use the reverse side of the file image to laser etch the reverse side of the mirror. It will show up correctly in the mirror.

The best way to etch glass with a consistent curve, such as glass or bottles, you can use a tumbler or chuck spin attachment.

How to Laser Engrave Glass

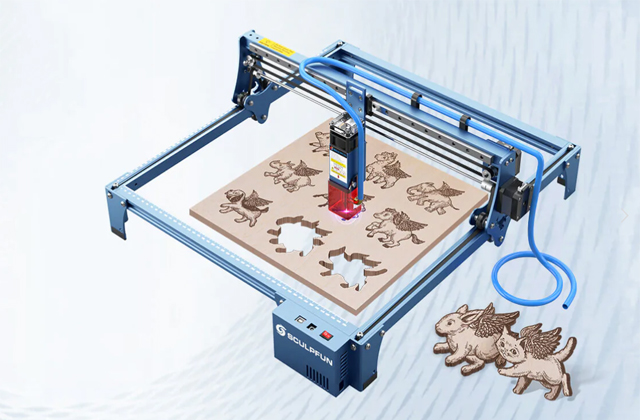

Lasers are easiest to use on flat surfaces. That is, they require a specific focal length or distance between the lens and the surface being marked. Lasers are very limited when the item to be marked is curved. There are a few tricks here to provide some flexibility, but even then the distance around the curvature of the project is strictly limited.

When engraving beer mugs, wine glasses, vases, wine bottles, etc., using a swivel attachment can make the task easier, but variations in curvature and complex angles can still be a problem. Also, the handles on the cup can interfere as they can protrude enough to actually hit the lens assembly when the cup is spun in the swivel attachment