Compared with other machines, laser engravers are the perfect choice to achieve precision work. With the help of a laser beam, laser engraving will perfectly carve and etch images or designs on soft metal, wood, rubber, acrylic and other materials (especially delicate ones) with higher accuracy than traditional saws or cutting machines.

Therefore, when purchasing this laser engraver, you must consider your working material for the best choice. Here are some suggestions to help you determine an apt model.

Plastic - To sculpt any design on plastic, it is best to use a plastic CO2 or diode laser engraver machine. Compared with traditional laser engraving machines, this engraving machine can easily and accurately etch plastic without melting it.

Metal - You can easily carve metal, making it perfect for necklaces, brand tags, and key chains. To make it precise and accurate, you have to use a CO2 laser engraver and a desktop laser engraver to carve a variety of metals.

Paper - The use of CO2 laser engraver and diode desktop laser engraver is the best choice for cutting or engraving on paper.

Glass - CO2 and diode laser engraving machines are your perfect partner when carving trophies, cups, and prizes on glass. Because it is fragile and delicate, traditional engraving machines will not be the right choice for precise and durable engraving.

Types Of Laser Engraving Machines:

There are three main types of laser engraving machines -diode, CO2, and fiber. This is a detailed explanation to give you an idea of these types and help you choose the right one for your needs.

CO2 engraving laser machine - This engraving machine uses a carbon dioxide beam to penetrate the material, and despite the inefficiency level it offers, it is ideal for a wide range of applications for engraving and cutting non-metallic materials such as wood, fabric, leather, and paper.

Fiber laser Engraving machine - In this type, a strong light is pumped through its fiber cable to produce a strong laser beam, and the cable is doped with ytterbium to release high capacity energy as photons.

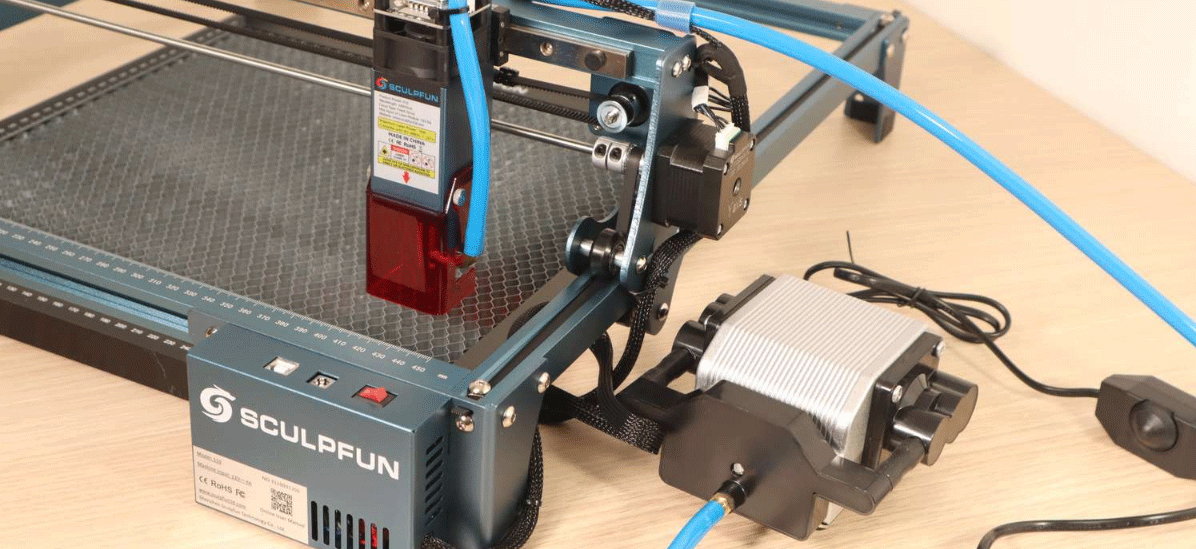

Diode laser engraving machine -a popular laser cutter and engraver, widely used by manufacturers and hobbyists. A diode is a photoelectric device that converts electrical energy into light. Thus, it uses high-intensity coherent light to carve images or designs on objects. Examples: Sculpfun, Atomstack, Ortur, etc.

How Does Laser Engraving Machine Work?

A design is created or initiated by computer software or application, which is then transferred to the carving tool. The machine uses a laser beam and computer-controlled motors to perfectly sculpt objects. Set the laser beam to reflect through the mirror and focus on the exact area where you want to produce the desired etching design. While performing this process, we noticed that the tool generates smoke and heat. Therefore, prefer engraving machines with built-in cooling fans and choose tools specifically designed to do the job you expect. Sculpfun S10 has an air assist device, which can quickly cool the surface temperature of the cutting object to avoid damage.

Is There Any Material I can't Cut With This Laser Engraver?

While we can cut thin metals, wood, fabrics, and other materials using excellent laser cutters, some materials cannot be cut with this laser. They may damage or destroy materials. Here are some details.

Thick polycarbonate - Various laser cutting Windows are made of polycarbonate. Since the material absorbs infrared radiation, it will not allow the tool to cut polycarbonate with a thickness of more than 1 mm.

PVC - Cutting PVC with a laser cutter can damage its controller, cause rust on the metal parts of the machine, and also damage the lenses.

Polystyrene foam - Since it is a fire hazard, you must avoid using laser cutters and engraving machines. It may also melt quickly and easily.

Abs-tend to catch fire and cause molten viscous deposits on the cut mesh, it is best to avoid this material which is difficult to carve or cut.

Fiberglass - often creates dangerous fumes when cut. You have to avoid them completely.