Laser technology can be used not only for welding, but also for cutting, engraving, and marking objects. In fact, lasers allow you to operate on a large number of objects without having to be processed by removing small amounts of material (thus creating cuts) or even cutting metals of different thicknesses, in order to obtain precise results and special aesthetics in a short period of time There is a risk of damage or deformation of different parts of the object.

Laser Marking: How It Works

Laser marking exploits the properties of lasers to achieve precise and fast results: the laser beam emitted by the marking machine is actually delivered to a small part of the surface of the object to be engraved, marked, or cut. Here, the laser beam transfers energy in the form of heat to the material that makes up the object. This creates an incision whose depth can be varied according to different needs.

The same technique can be used to obtain other types of results: if the object is to be not only surface-engraved but also depth-marked, the intensity of the laser beam can be increased and the exposure time of the laser beam longer. In this way, a true excavation will be obtained, which may be small in diameter but still deep, unlike marks made by other mechanical means.

Finally, using the same technique, metal can be cut so that the laser beam repeatedly passes over the same part of the surface. In this way, more and more material can be removed little by little until a cut is created.

Laser engraving and marking are particularly precise and defined; the laser can achieve thinner engravings and act on fragile or delicate parts of objects, as well as operate on surfaces that are difficult to reach with traditional engraving tools. However, the potential of laser engraver doesn't stop there: with this technology - supplemented by special software - particularly refined aesthetics can be achieved. Bas-reliefs of different depths can be produced by the laser, and even the color of the starting material can be changed, as the laser beam striking the metal can be calibrated to obtain this type of result.

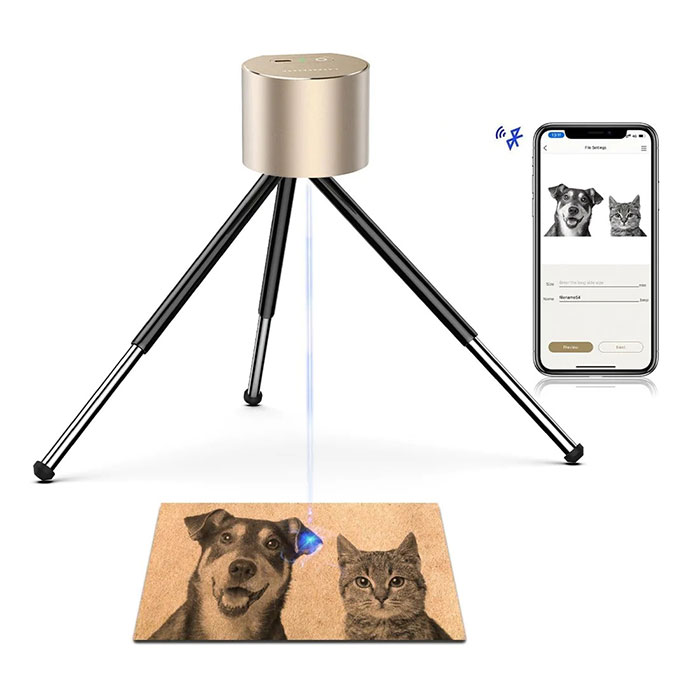

Recommend a handheld laser engraving machine LaserPecker 2, which is easy to operate and has a very good marking effect. It is suitable for large items and small items. When you engrave large items, you can use the scroll engraving mode, which is no longer limited by the engraving area.

Application Areas of Laser Marking

Laser marking can be used to engrave or cut a large number of metals such as:

- Gold

- Silver

- platinum

- Steel

- Titanium

- Palladio

- Brass

- Many more

This means that laser marking can be used in a wide range of industrial fields: it can be used for gold jewelry, for engraving all types of jewelry, regardless of their shape and aesthetic characteristics, but also in industrial fields especially for all items produced by a specific company Permanently marked to guarantee their traceability.

Why choose laser marking

Laser marking guarantees numerous advantages, as this technology enables perfect results from an aesthetic point of view. The precision of the laser ensures that objects are engraved or marked in a precise and permanent manner, without any smudges from cuts or abrasions on the treated surface. This allows for very "clean" results, with high resolution, and can handle even precious and delicate objects without risking damage to them.

Laser marking also has undeniable advantages, it is a technology that significantly reduces processing time. The power reached by the laser can quickly engrave large quantities of material, and if the marking machine is equipped with sufficient software, the productivity of the company using it can be significantly increased, both in terms of production speed and the variety of processes suggested to customers. The potential of the laser also extends the full range of materials and objects processed, as, by the power applied to the beam, impeccable results can be obtained even on surfaces or materials that are often difficult to engrave. In addition, laser marking can achieve long-lasting results: marked objects are neither corroded nor damaged, so their engravings remain clearly visible at all times in line with the quality standards of industrial production.

If you want to find out which laser marker model is best for your type of business and how choosing a similar tool can help grow your business, check out the HTPOW catalog and contact us! We have many brands of laser engraving cutting machines, you can choose such as Ortur Laser Master 3, xTool D1 Pro, etc.