When it comes to manufacturing design, a laser engraver can have a beneficial impact on any product. Cost and quality are the two main factors affecting the marketability of any product, and laser cutting can produce high-quality components at a lower overall cost, thus allowing for a more affordable and better-quality product. The same is true for home laser engraving. Using Ortur Laser Master 3 can cut the working time you spend at least in half when using home laser engraving.

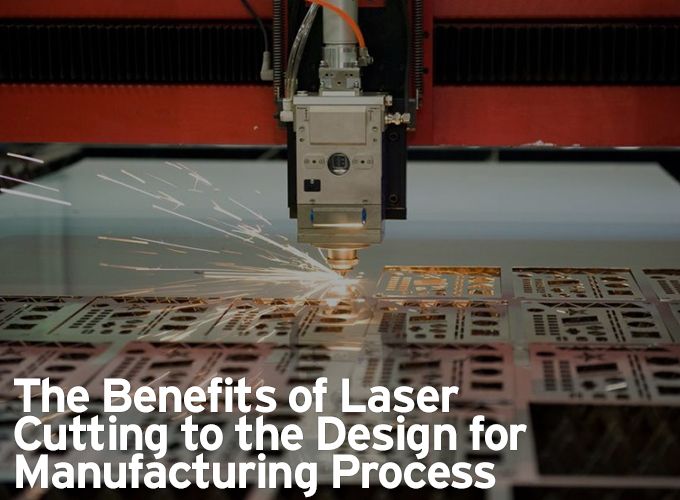

Benefits of Laser Cutting for Manufacturing Process Design

The concept of design for manufacturability (DFM) is not new. For decades, manufacturers have sought to make the manufacturing process simpler and more efficient by validating that designs can actually be manufactured early in the development process, saving time and money and speeding up time to market for new products while ensuring optimal productivity. Through research, HTPOW also found that home laser engraving machines are more and more popular and used by more and more users, so HTPOW cooperates with manufacturers such as xTool, Ortur, Sculpfun, LaserPecker and Atomstack to bring customers the most cost-effective and the best home laser engraving machine.

Most DFM efforts have focused on simplicity; that is, trying to reduce the complexity of the design to prevent complicating the manufacturing process. In general, the more complex the design, the more difficult it is to manufacture—and the difficulty is cost. However, the development of new technologies such as laser cutting has made it easier to manufacture more complex products. Rather than simplifying the product itself, a laser cutter simplifies the process of making it, making it simpler, enabling greater complexity in less time — and increasing innovation.

The Most Basic Benefits of Laser Cutting

In general, laser cutting does offer some substantial benefits to the manufacturing process. For starters, laser cutters can be customized to cut virtually any material of any thickness to precise specifications. It is fast, accurate, and can be quickly and easily adjusted to meet changing needs of the market or a specific product. It's also a cleaner process than most cutting options, as it requires little secondary cleanup.

Of course, it has some downsides as it does use more power than other types of cutters and requires more training to operate properly as a poorly adjusted laser can burn materials or not cut them cleanly. While laser cutting is generally more expensive than other types of processes, such as wet cutting, the benefits often far outweigh these costs.

In terms of manufacturing design, laser cutting technology can have a beneficial impact on any product. Cost and quality are the two main factors affecting the marketability of any product, and laser cutting can produce high-quality components at a lower overall cost, thus allowing for a more affordable and better-quality product. Laser cutting also makes the manufacturing process more flexible. Lasers operate several times hotter than the sun, so they can cleanly and accurately cut nearly any material, from the strongest alloys all the way to the thinnest polymers. This flexibility aids in the design of manufacturing processes because engineers are not limited by the range of materials they can work with. Materials do not have to be selected based solely on cost or availability,

Laser cutting also allows for more creativity in the product development process. Lasers are not limited by geometry, so parts don't have to fit within the capabilities of a laser cutter. Because the laser itself never actually touches the part being cut, materials can be oriented in any way, which allows them to be cut into any shape or form. In many cases, the precision cuts made by the laser require little post-cutting treatment, which also speeds up the manufacturing process.

Some Notes

While laser cutting is a useful tool when it comes to manufacturing designs, engineers need to consider a few things.

The first is the possibility of over-engineering. Often, engineers who understand the capabilities of a laser cutter will design a part or product with extremely tight tolerances. While a tolerance of 5/1000th of an inch is sometimes required, usually 1/16th of an inch is sufficient. Tighter tolerances increase the cost and production time of the product and can lead to waste.

Choosing the right material is another consideration. Likewise, just because a laser can cut material doesn't mean that material is right for a particular project. Design for manufacturability means making sure that the design can actually be put into practice. Choosing the right material can mean the difference between a design that can be manufactured and one that cannot.

Laser cutting is just one technology that improves productivity. However, it has become a crucial factor and has helped many products get to market faster and at a lower costs. Laser engraving technology will be more and more valued and liked by all factories in the future manufacturing process.