These days, it's easier than ever to create designs and prototypes with a laser engraver or cutter. But which machine should you use? LaserPecker 2 lets you cut many different types of materials, while Ortur Laser Master 3 and xTool D1 Pro can both engrave on wood, acrylics, metals, and other materials. Here's how these three machines compare:

What is the difference between laser cutting and laser engraving?

Laser cutting is a process that cuts materials by removing material from the surface of a workpiece.

Laser engraving is a process that creates text and images on a workpiece by removing material from the surface.

What are the advantages and disadvantages of laser cutting?

The advantages of laser cutting are as follows:

- Laser cutting is a clean and precise process.

- Laser cutting is a fast process.

- Laser cutting is a cost-effective process, since it cuts the material in one go, making it save on materials and time.

Laser cutting is a great technology that has many advantages. But not everything is perfect. The disadvantages of laser cutting are as follows:

- Laser cutting is an expensive process.

- It is a time-consuming process.

- The laser can be dangerous to the operator and bystanders

What can LaserPecker 2 cut?

LaserPecker 2 can cut a variety of materials, including wood, acrylic, leather, paper, and cardboard. It can also engrave on a glass.

What can LaserPecker 2 engrave?

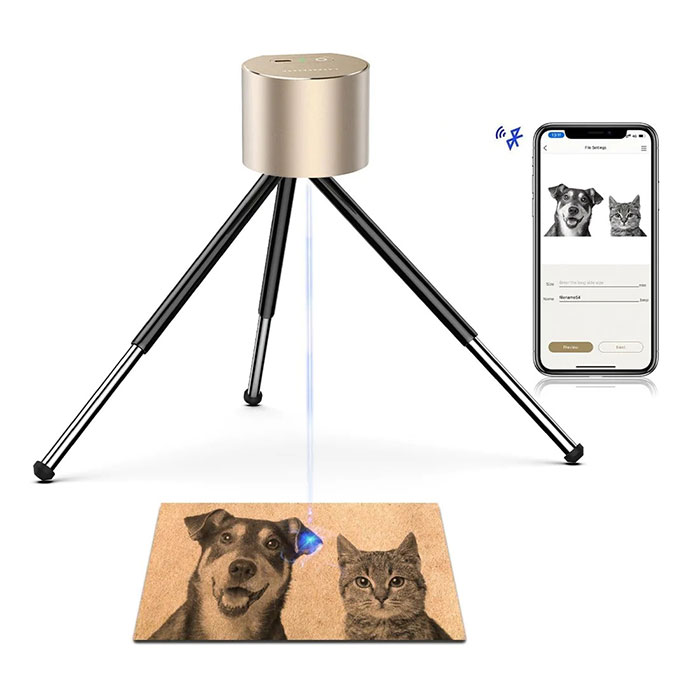

LaserPecker 2 is a laser engraver that allows you to print words, images, and logos on a variety of materials. The machine can engrave wood, leather, plastic, acrylic, and even glass. It doesn't require any additional accessories or extra equipment. The laser pecker 2 comes with all the necessary tools needed to create your design.

It's important to note that not all materials can be engraved with this machine because some don't have enough reflectivity or absorbency for them to work correctly. Also, it’s important to know that if you use non-metallic materials like wood or plexiglass then they will need some sort of protection against burning (either paint or varnish).

What can Ortur Laser Master 3 cut?

Laser-cutting machines can do a lot more than just cut metal and wood. They can also cut through other materials like acrylic, leather, paper, and cloth. A laser engraving machine will not only engrave these materials but also the human skin if you’re into that kind of thing. With that said, let’s take a look at some examples of what Ortur Laser Master 3 can cut:

-

Steel

-

Wood

-

Acrylic

-

Leather

What can Ortur Laser Master 3 engrave?

The laser engraving machine can be used to engrave on a variety of materials, such as wood, bamboo, plastic, ceramic, metals, and so on. It can also be used to engrave rubber and leather. The material that is suitable for laser engraving is not limited to the above list. If you want to make laser engraved products such as furniture accessories or gifts for friends and family members who are important to you then this machine will help you do it easily with any kind of material!

What can xTool D1 Pro cut?

The xTool D1 Pro can cut wood, bamboo, plexiglass, acrylic, and paper.

Cardboard will also be able to be cut but only at a limited thickness of 1/8" or 3mm.

What can xTool D1 Pro engrave?

The Xtool D1 Pro engraver machine is able to engrave on any material that is conductive. With its powerful laser, you can make your mark on wood, acrylic, leather, paper and fabric as well as cardboard or other materials. You can even use the Xtool D1 Pro to engrave on glass and mirrors with the right lens!

The machine comes with a metal lens which makes it possible for you to engrave onto metal surfaces such as gold or silver products. It also has an optional diamond lens so that you can create beautiful etchings in stone with ease!

These three laser engravers will help you bring your ideas to life.

Laser Engraver: These machines are great for making detailed, small designs. The laser beam traces the shape of your design onto any material you put over it.

We hope this article has helped you understand the differences between laser cutting and laser engraving. We also hope that it has given you some insight into which machine may be best for your project, whether that is an intricate design for jewelry or a simple logo for your company’s business cards. If you have any questions about our products or want to learn more about what we do at LaserPecker, please contact us today!