Laser engraving & laser cutting of wood

Would you like to laser-process wood? Good idea! Wood is an ideal material for laser engraving and cutting. The concentrated heat of the laser beam cleanly removes layers from the wood surface. Laser cutting of complex templates made from wood produces precise edges to achieve perfect cutting results. It can also be used to make filaments cuts and engravings that are not possible with other woodworking methods, such as sawing or milling. In addition, the wood laser has no annoying debris and does not require post-processing.

With our many years of experience in laser engraving and laser cutting of wood, we will explain the most important points you need to know.

Applications of laser engraving wood

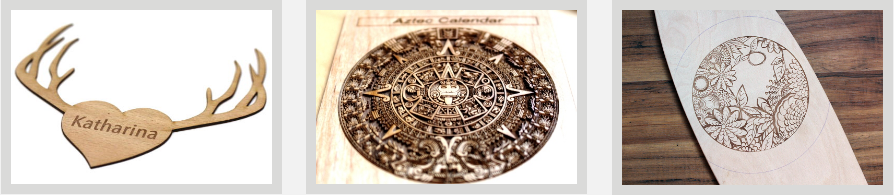

As a versatile material, wood offers unimaginable possibilities when combined with laser engraving and laser cutting. Through wood carving, proverbs, names, photographs, or logos can be carved into woodwork, such as:

- Picture frame

- Breakfast plate

- desktop

- The guitar

- Tree slices

- The pencil

- The wooden case

- Skateboard/longboard

- Viking chess or kubb games

- Business CARDS, etc.

Be improved. Particularly impressive results can be achieved using veneered and painted wooden items, such as our compass in wooden cases. Remove the top layer of paint or veneer to expose the layer below.

Laser cutting applications for wood

Using wood laser cutting, product parts can be used for:

- toy

- Decorative items, such as small wooden signs with names on them

- souvenir

- Wooden sign

- Interior objects, such as inscriptions on walls

- Christmas decorations, such as individual candle arches

- Cake decoration

- The instrument

- Building model

- As well as Mosaic and works in handicrafts and so on

Fast, flexible, and accurate implementation. The wood is made of high-quality laser engraving and laser cutting.

The Sculpfun S10 laser engraver is a new model after the Sculpfun S9. Although the S30 series laser engraving machine has been released, the popularity of the Sculpfun S10 is still unabated. It features a 10W laser module which is ready for an air assist system. It should offer a good cutting performance. It is suitable for hobby or even professional work as it has enough ability to run a small business with it! Are you still interested? Click the picture for details.

What kind of wood is used for laser processing?

Generally, low-fiber wood with a relatively uniform texture (such as beech, cherry, or poplar) provides very good and high-contrast carving results. Fibrous and granular wood such as bamboo is less suitable for carving.

The texture of the wood plays an important role when laser engraving wood, as it has a significant impact on the color and depth of the engraving. Carvings on poplar or birch are relatively light and subtle because of the low contrast. Beech or oak, on the other hand, produces a very deep carving effect. Add a layer of glaze for more emphasis on carving.

This is how wood engraving and wood cutting work with lasers

When laser cutting wood, the laser beam in the material cutting gap will cause the temperature to rise above the wood sublimation temperature. As a result, the evaporated wood escapes as smoke and dissipates the incoming heat. As a result, the surrounding material is subjected to only slight thermal stress. However, depending on the type of wood, a brownish discoloration can occur when cutting the edges.

The treatment time also depends on the respective wood. Therefore, the characteristics of the wood (density, resin content, etc.) have a significant impact on the processing results.

The wood source is wide, the material is light, the hardness is low, the decoration is diverse, the plasticity is strong, and the low carbon environmental protection, is used widely in the handicraft processing. The production and processing methods of wood handicrafts are quite diverse, such as traditional manual, semi-mechanical processing, pure mechanical processing and so on. The types of wood crafts are very complex, and according to the classification of the wood itself, the exquisite degree of processing requirements will be different. If common pine, cypress, the cost is lower, can be used at the processing of a few household decorations, had better be able to realize batch processing, to the requirement of processing fineness degree is not high. And to high-end wood, such as golden silk nanmu, Huanghua pear wood, mahogany, its to the requirement of processing sophisticated degree is higher, because this should use all kinds of processing technology proficiently. Wooden handicrafts have strong ornamental value, and some of them have high practical value, economic value and even collection value. By analyzing the application of laser engraving technology, the processing quality of wood handicrafts can be improved, and the realization of quantitative production can be promoted.

Advantages of laser engraving and laser cutting of wood

- No debris fast cleaning processing

- Filaments and precise cuts

- No time-consuming post-processing, such as filing, polishing, etc.

- There are no acquisition costs for jigsaw, jigsaw, reel saw, router, etc.

- Unlike milling, there are no expensive setup costs

- We personalize standard items quickly and easily

- This is how unique wooden (promotional) gifts are made

.jpg)