More and more stores now offer the option to customize purchases by adding names, images or emotional phrases to items. This approach to personalization has several benefits: it differentiates the item, making it more special to the recipient, and it increases its value to the manufacturer.

If you're a hobbyist, a laser engraver probably falls into the "own" category when you think of a tool arsenal to assemble in a woodworking shop.

But I'll say a little more and say it's pretty nice to have. If you're running a custom woodworking business in your own shop, laser engraving machines may gradually become a "must have" category when it comes to competitive advantage and profitability.

How Does a Laser Engraver Work?

The term "laser" stands for optical amplification of stimulated emission. Fiber lasers emit a focused beam of light to burn objects. The laser is controlled by a robotic arm that draws its route on the X/Y grid.

The user controls the path of the laser by supplying artwork from a computer, using specialized software (usually supplied with the laser engraver) to lay out the artwork and format it for the specific engraver being used.

To control the depth of cut, the operator has two variables that can be adjusted. The first is the speed of the robotic arm, which can move quickly for lighter surface engraving, or slower for deeper work, such as cutting. Another variable that can be adjusted based on the material and desired effect is the percentage of power that will be used for a given operation.

What can you do with a laser engraver?

There are many materials that can be cut, and depending on the power of the machine, even more can be engraved with a fiber laser engraver. Wood and processed wood products, such as plywood, MDF, particleboard, melamine, and more, are ideal for cutting and engraving. But you can also engrave on countless other materials, such as glass, acrylic, coated metal, rubber, cork, leather, and ceramic. I've created projects on many of these materials, and after some trying to adjust the correct power and speed settings, I've been able to produce some great results. Some examples include:

Small Decoupage Orojects

Picture of carved wooden coasters

I've tried several hardwoods and softwoods, both solid and veneer, and found them all great for cutting and carving. Using my 40 watt laser, I am able to cut ¼” thick wood with great precision, which makes making things like keychains and coasters a lot of fun because I can engrave images and cut shapes in one setup .

Logo Making

Picture of a wooden engraved sign

I made several signs on the wood and was impressed with the depth of cut and the ease of incorporating lots of clip art into the project. Now, sign making is as easy as printing to a laser printer.

Customized Furniture

A picture of a large wooden table with an S engraved on it

I built a live sidebar for a client and carved a large "S" (his initials) on the table. This is a great way to customize this item and make it a special heirloom.

Anodized Aluminum

Image of Laser Engraving on Anodized Aluminum

I bought an anodized aluminum sheet and made some projects out of it. The laser leaves crisp lines that pass through the coated surface, producing an excellent image.

Leather

Laser Engraving on Leather Cups

I found that the laser engraver produced surprisingly clear images on leather that stood out well even on black leather, as shown in these leather dice cups.

Glass

Laser engraving on glass

Laser engravers produce beautiful results when engraving on flat glass and drinking glasses.

Using a Laser Engraver:

Now that you've seen some awesome projects you can make with a laser engraver, how exactly do you use it? Most of the work done for a laser engraving project is done on your computer before you use the machine. Depending on the manufacturer, several different methods are available:

Laser Engraving Machine Design Application

There are special software products designed specifically for use with laser engravers. These apps allow users to import artwork as well as create some basic illustrations inside the app itself. The output of the application can be put on a memory stick and transmitted to the laser engraver via "sneaker-net", or if the laser supports a direct interface, the application can send the job directly to the engraver via a wired or wireless connection. The product I use It's called RD Works and it's included with my laser.

Print Interface

Some lasers include driver software that works like a print driver you might use on a traditional laser printer, acting as a "translator" between any application and the laser engraver. With this type of setup, you can create a layout in any application (even Microsoft PowerPoint) and then send the output file to the laser like a print job. When you send it to the laser, the laser driver pops up on the screen and allows you to configure any project-specific laser settings, such as power and speed, before passing the file to the laser.

What It Takes to Get Started with a Laser Engraver

First, you need to choose a laser engraver. Laser engravers are available from a number of manufacturers, with price options ranging from a few hundred dollars to thousands of dollars. They range in power (measured by the power rating of the laser unit) from 10W to over 100W.

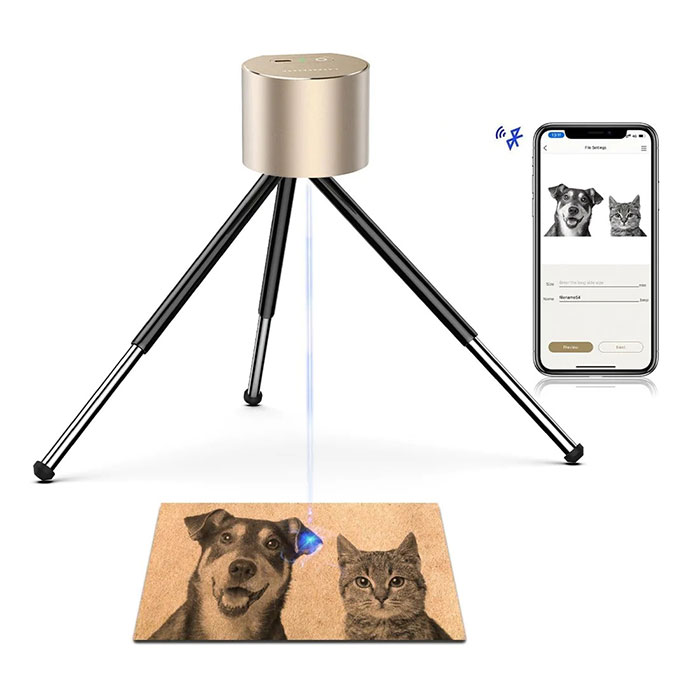

If you don't know how to choose a laser engraver, then you can buy it from our website, our online store has many brands and models of laser engravers that are very popular right now, for example, everyone's favorite Ortur Laser Master 3, and Best LaserPecker 2 for engraving patterns.

Additionally, you will need several additional components to ensure proper maintenance of the laser. Because the laser gets hot during operation, you need a way to keep it cool. Most entry-level machines are liquid-cooled, so you'll need a cooling unit to circulate water through the laser to keep it cool. Work with the laser manufacturer to match your laser with an appropriately sized cooler, do not skip this component as doing so will significantly reduce the life of the laser.

The xTool D1 Pro is equipped with water cooling and fan cooling devices, which you can buy with confidence, and the carving accuracy of the xTool D1 Pro is very fine.

The laser produces a lot of smoke as it vaporizes the material. You need a system to extract the smoke from the laser. You will need to run the plumbing outside or add a filtration system that will clean the exhaust from the system. I lined mine out the window and created a sealed baffle that I installed on the window frame.

Looking to The Future

I look forward to years of creative and fun projects with my laser engraver. I'm always thinking of new ways to use it and who knows where this path will lead me. How about you? What would you do with a laser engraver in your shop?