If you're a hobbyist, crafter, DIYer, or small entrepreneur, then you know that laser cutting is a popular and fun way to realize your creativity on a variety of materials. But what if you're not quite sure how air assist can help the laser-cutting process? This blog post will explain the basics of air assist to help you learn how to improve your results when laser cutting. We'll test three different laser engravers to show you how they can make your laser cutting even better!

What does air assist do to a laser cutting machine?

Air assist is a stream of compressed air that is blown toward the material being cut. The idea is that the airflow provided by the compressor helps cool the material, prevents overheating of the object being cut and causes charring, and also helps remove any debris and fumes created during the laser cutting process. The Sculpfun S10 is equipped with high-speed air assist nozzles. What makes this nozzle different is that it has an advanced hydrodynamic design that makes better use of air pressure. When using the same air compressor, the S10 has a faster air jet for cleaner, more precise cuts with no stains on the cut surface.

Air assist also helps to prolong the life of the laser cutting machine as it protects the lens by preventing fumes from sticking to the laser lens, and it also prevents the material from overheating from the laser cutting process. High and fire, your safety using the laser engraving machine is more secure.

Why are we testing different air aids?

The size and shape of nozzles and compressors, as well as related components, can affect the performance of the air assist. Moreover, the optical power of the laser engraver also affects its efficiency. We tested three popular laser engravers, experimenting with and without air assistance to test the best option for different materials and cutting needs.

What did we test?

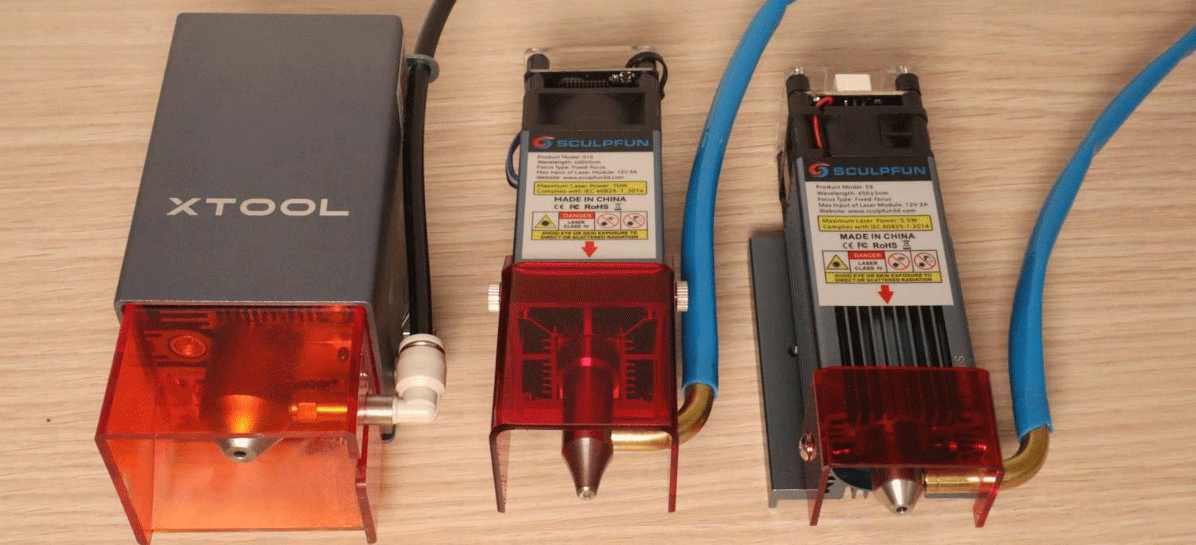

In the test, we tested the air-assisted system on three popular laser engraving machines on the market - 20W XTool D1 Pro, 10W Sculpfun s10, and 5W Sculpfun S9. The output of the air pump used by Sculpfun and xTool is 30L/min. Only the hose fittings and speed controls differ.

XTool and Sculpfun are both manufacturers that produce engraving machines that support Lightburn and LaserGRBL control software, we decided to test three machines with different prices and different powers, and the difference in the performance shown can also help us Get an overview of how air assist performs on laser heads with different optical power outputs.

Testing process

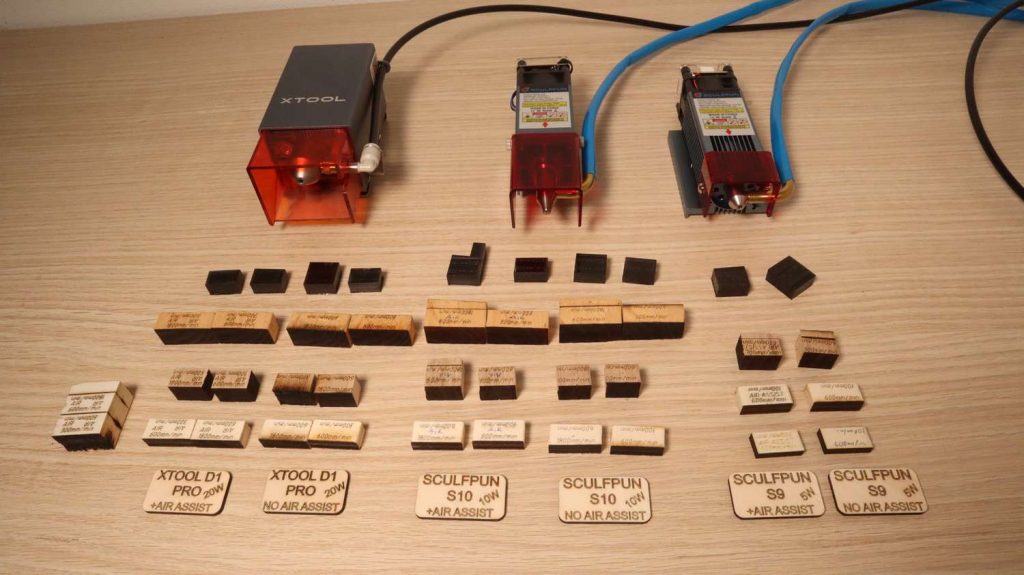

We tried cutting some very thick materials with these three laser engravers to see what the cleanliness of the tabletop would be with and without air assist.

We will be cutting 10mm poplar plywood, 15mm paulownia wood, 17mm general construction timber, and 10mm thick black acrylic. We also tried pushing the xTool D1 Pro 20W to the limit and tried cutting 18mm (thick poplar plywood) with air assist.

We did cutting tests at three speeds, 1800, 600 and 300 mm/min, but for the Sculpfun S9 we only used the slower two speeds as this machine has only 5W which is not suitable for cutting , only suitable for engraving. We tested different cutting speeds to find the best speed for each machine.

Test Results for the xTool D1 Pro 20W Air Assist System

xTool D1 Pro is a very common laser engraver, also very popular among hobbyists, it can be considered as a real laser cutting machine due to its powerful four-diode compression point laser head, this one Machine tips are of high quality and high performance.

First, take a look at a photo below that shows the xTool D1 Pro 20W laser engraver cutting with and without air assist. You will find that cutting wood with air assist results in cleaner edges and less smoke stains on the surface of the cut edge.

10mm thick poplar plywood cutting test results

Using this material, the cutting performance of the xTool D1 Pro was similar with or without air assist, requiring the same number of passes to cut, but using air assist resulted in a cleaner cut surface.

data

1800 mm/min: 17 unassisted passes / 16 assisted passes

300mm/min: 3 times without assistance / 2 times with assistance

15mm thick paulownia wood cutting test results

This wood is lightweight and ideal for model making. In this set of tests, the cutting performance of the xTool D1 Pro 20W with air assist was much different, and without it, the wood had a lot of charring.

data:

1800 mm/min: 25 unassisted/10 assisted

600 mm/min: >15 unassisted passes / 4 assisted passes

300 mm/min: 5 unassisted/2 assisted

Test Results for the Sculpfun S10 (10W) Air Assist System

The Sculpfun S10 laser head is a dual diode compression spot module that comes pre-installed with air assist, you only need to buy the compressor. If you want to learn more about this laser engraver, read our Sculpfun S10 review.

Below the photo you will find an explanation of the analytical data, which contains the exact number of passes required to cut a given workpiece at a specific speed.

10mm thick poplar plywood cutting test

Using this material, the Sculpfun S10 Laser Engraver has similar cutting performance with and without air assist, but with air assist the surface is cleaner, with less charring and significantly improved cutting performance.

data:

1800 mm/min: >50 unassisted passes / 38 assisted passes

300mm/min: 5 times without assistance / 4 times with assistance

17mm thick pine wood cutting test

Next, we started cutting pine lumber, an inexpensive wood used in construction. , this wood will give off a lot of smoke, but the laser cutting and air assist give the Sculpfun S10 great performance, cutting objects very cleanly, one of the cleanest cuts we've ever seen!

data:

1800 mm/min: >50 unassisted />50 assisted

300 mm/min: >15 unassisted passes / 6 assisted passes

10mm (3/5") thick black acrylic cut test

Acrylic is easy to melt when heated, so cutting it is very easy to damage the cutting object, cutting this kind of object is very suitable to use air assist, because it helps to cool the material, so it does not melt when cutting. The Sculpfun S10 shows a significant performance boost with accessibility turned on!

data:

1800 mm/min: >50 unassisted/<50 assisted

300 mm/min: 11 unassisted passes / 9 assisted passes

Test Results of the Sculpfun S9 (5W) Air Assist System

Although 5W of power is not suitable for cutting, the S9 is actually a very powerful laser cutter! You can use it to cut any thin material. The S9 initially only comes with a standard reticle, no nozzle, which you will need to purchase separately as an upgrade air assist kit/kit.

With the Sculpfun S9 laser engraver, only use the slower two speeds (600mm/min and 300mm/min) because this laser engraver has the least power and cannot cut as fast as the other two.

6mm (1/4") and 10mm (3/5") thick poplar plywood cutting test

With this material, air assist has little effect on the cutting speed of the Sculpfun S9, but the cutting edge is cleaner when using the assist.

data:

6mm poplar plywood:

600mm/min: 6 times without assistance/5 times with assistance

300mm/min: 3 times without assistance/2.5 times with assistance

10mm (3/5") thick black acrylic

The Sculpfun S9 laser engraver had a bit of a hard time cutting such thick acrylic sheets because of its low output. But it still showed a good performance boost when cutting black acrylic at low speeds.

result:

600 mm/min: >25 unassisted />25 assisted

300 mm/min: >20 unassisted passes / 17 assisted passes

In conclusion

Air assist is an essential part of the laser cutting process and not only provides a cleaner cut, but also minimizes smoke stains and charring. At the same time, it will also improve your cutting efficiency. This is also an important safety feature, as it avoids possible fire situations during cutting work. If you are looking for a way to improve your laser cutting results, using air assist is a great option. Through the above comparison results, do you have a heartbeat machine? No matter which machine you prefer, you can open the HTPOW website to choose to buy, the website is doing activities, and the maximum discount is 30%! It's better to take action, go and see it!

thanks for reading!

.jpg)