Laser cutting and laser engraving open up completely new possibilities when processing paper, cardboard or cardboard. For example, thanks to the rapid development of modern laser technology, HTPOW can offer you a laser engraver suitable for paper cutting and engraving at an affordable price. With laser technology, even the most delicate details can be processed contactlessly on any kind of paper product, compared to conventional punching technology. So: instead of having paper and cardboard perforated, read on to learn everything you need to know about laser engraving and laser cutting paper.

Laser Engraving And Laser Cutting Paper Applications

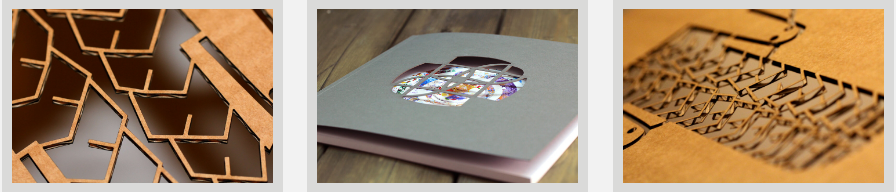

Laser cutting or engraving of paper is ideal for creating the finest geometries. With a laser engraving machine, you can not only simply cut paper to a certain size, you can also order filigree shapes from greeting and invitation cards, covers, posters and more. In addition to laser cutting paper, engraving is also possible, so you can engrave the following applications on paper without any problems. It should be noted that you need to use a lower power when cutting paper, the power is too high paper can easily burn, a lower power laser engraving machine such as Sculpfun S9 only 5w power, although it can handle some of the more fragile materials, but it is powerful, he can also handle a little more complex materials such as stainless steel, is a more cost-effective machine.

- Folded edges

- Logos

- Engraving

- pictures

- Perforation

How Laser Engraving And Laser Cutting Of Paper Works

When laser engraving or laser cutting paper, the laser beam causes an increase in temperature in the cut slits of the material, exceeding the sublimation temperature of the paper, similar to wood. As a result, the "vaporized" paper escapes as smoke and dissipates the introduced heat. As a result, the surrounding material is only slightly affected by the heat. Even with a filamentous profile, the paper remains smoke-free and without burnt edges. In contrast to perforation, non-contact laser processing also does not result in crushed material. If you need to engrave cardboard such as cardboard, you can choose to buy the Sculpfun S10, which is suitable for cutting thicker paper and it comes with an air assist that reduces the appearance of smoke and also prevents the paper from burning. If you need to engrave other complex materials such as metal and stone, you can buy theSculpfun S30 Pro Max, the latest model from Sculpfun, which is powerful and comes with a complete air assist system.

Advantages Of Laser Engraved And Laser Cut Paper

- Cut edges do not show the scars that occur with perforation

- Precise, clean cutting of very fine contours

- Versatile design options such as bending, engraving, perforating, etc.

- Clean, chip-free processing

- Entirely in-house designs can be achieved by combining laser cutting and laser engraving

- Paper as an inexpensive material that can be personalized quickly and easily

- This is how unique (promotional) gifts and design items are created

- We accept single and continuous orders

- Compared to printing, laser engraving is permanent

.jpg)