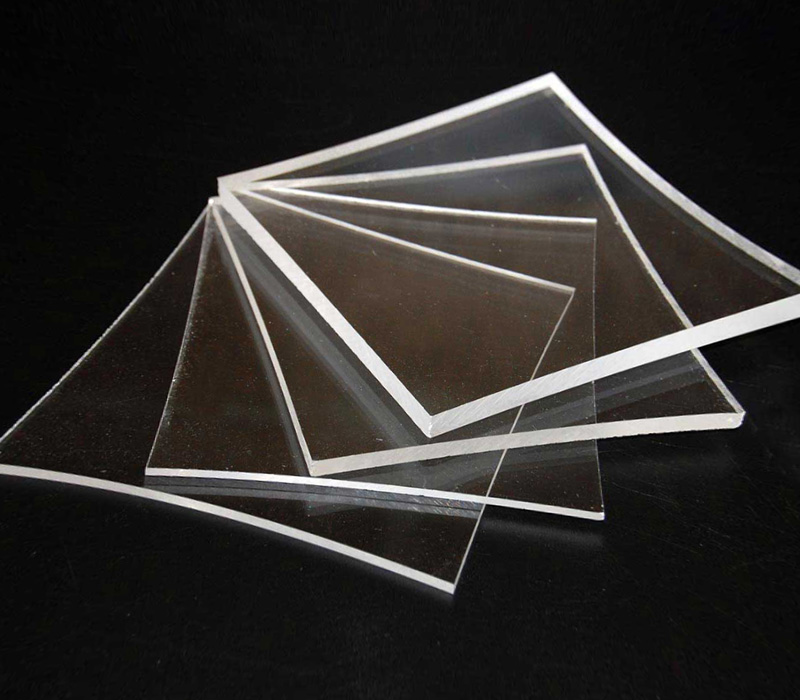

Acrylic or plexiglass is an affordable, versatile material with glass-like transparency and plastic-like durability.

By using the right laser engraver and following the correct technique you can create smooth-edged, and polished acrylic products.

Laser Cutting Acrylic

A laser cutter offers high precision and a smooth surface in addition to quick cutting speed.

The CO2 laser is best for cutting acrylics, as it works well even on clear acrylics. Typically, cutting 1mm thick acrylic requires a laser power of 10W, so it is recommended to use a high-energy CO2 laser rated at 60W or higher to treat acrylics.

A CO2 laser may even cut through transparent acrylics due to its wavelength (9 to 11 m), which the acrylic can easily absorb and evaporate.

A diode laser, in contrast, hand, will cut through transparent acrylic with no discernible effect on the workpiece. But atomstack s20 pro, the laser output power soars up with the latest generation of four 6W laser coupling technology, is able to cut off 8mm thick black acrylic board with only one pass. It's the world's first 20W optical power laser engraving machine.

Acrylic is a type of plastic, so you can apply a similar technique to laser engraving or cutting plastic.

Types of Acrylic Suitable for Laser Cutting

Acrylics are classified into two categories based on their production process: extruded acrylics and cast acrylics.

It is critical to understand both because they respond differently when subjected to laser processing.

Knowing the differences between the two can assist you in selecting the best one for your application.

Extruded Acrylic

Extruded acrylic is made by extruding an acrylic material through an opening of the desired thickness.

The extrusion process causes the material's mechanical characteristics to be non-uniform along the x and y axes.

It is relatively cheaper than cast acrylic and has superior optical characteristics.

Extruded acrylics have high impact resistance,is three times more durable than window glass of the same thickness while weighing 50% less.

Laser-cutting extruded acrylics will produce a clean cut with flame-polished edges.

The acrylic resin extruded by laser engraving machine will cause the engraving to be gray, making them unsuitable for engraving.

In general, extruded acrylic is easier to cut than cast acrylic of the same thickness and requires relatively less laser power.

Cast Acrylic

Cast acrylic is a high-quality acrylic produced by casting methyl methacrylate between two sheets of glass.

The glass and methyl methacrylate components then polymerize to form a piece of cast acrylic acid. In general, cast acrylic is easier to shape than extruded acrylic of the same thickness.

This manufacturing technique produces a homogeneous material with uniform mechanical characteristics in all directions. Since it is not ground up into powder before being formed, it lacks the inhomogeneity of some injection molding processes, in which variations in material can result in parts that warp.

Laser cutting cast acrylic will result in a good surface finish with some striation marks along the edge. Cast acrylic is comparatively more costly than extruded acrylic but offers better optical properties. It is highly recommended for laser engraving because of its excellent frosty-white output.

Laser Cutter Setup for Acrylic Cutting

Laser Power

A CO2 laser with a power rating of around 60W is recommended to cut through acrylic sheets as thick as 0.23 inches (6mm). A low-power diode laser can also be used to engrave acrylic and can even perform satisfactory cuts with multiple passes.Therefore, when selecting a laser for cutting acrylic, the power rating of the laser module is very important.

Cutting Speed

Laser cutting acrylics at low speed produces a glass-clear, flame polished edge without any burrs, but if you find chatter marks along the edge of the cut, then you should consider increasing the cutting speed. The cutting speed determines the surface finish of the cuts performed by laser cutting.Some types of acrylic can withstand a faster cutting speed.

When cutting acrylic sheets, it is recommended to set laser power at 80% with a low cutting speed of around 0.5 inches/sec (5mm/sec) for the best results. For high-quality raster engraving, the recommended laser power is 13%. Cutting of acrylic with CO2 laser, a detailed consideration - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Some quick tips on using an atomstack laser engraver for the best performance.

You can also refer to laser cutting thickness and speed table for determining the best laser settings for your application.

Air Assist

Air assist is not normally necessary for cutting thin sheets of acrylic, but it is beneficial when cutting thick sheets. Cutting multiple layers at once usually requires air assist to get the desired engraving quality.

When cutting acrylic, The air assist should be a low-pressure (about 0.2 bar) air assist with a large-size laser nozzle. Air assist should be turned on when using 0.25 and above laser power.

This low pressure and large size laser nozzle gives the acrylic enough time to cool while forming a glass transparent edge. A higher air pressure would significantly decrease the size of the laser-processed acrylic parts and would also reduce their clarity. #atomstack air assist

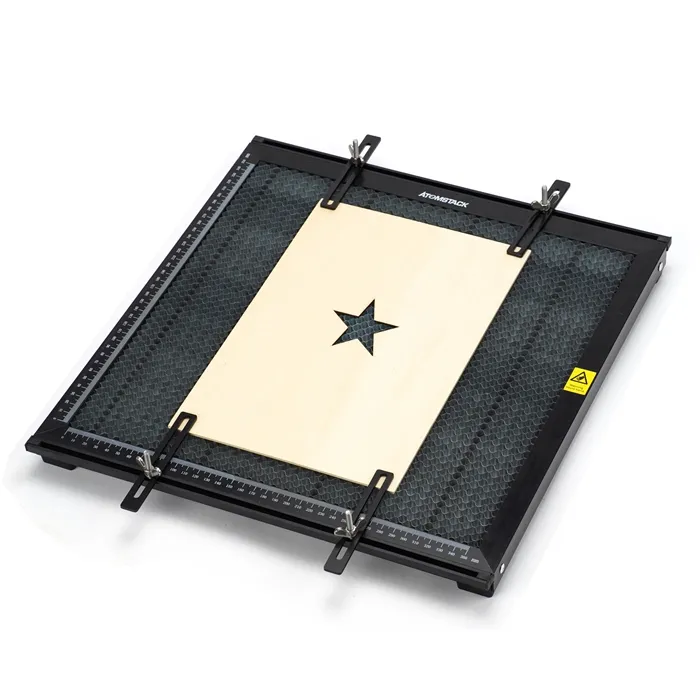

Cutting Table

When laser cutting acrylic, be sure to cut the internal geometry first, as the unsupported part will fall onto the table after cutting. Use a pin table to lift the acrylic workpiece off the table and prevent the reflected laser light from causing any defects in the workpiece. Save internal cuts for last to avoid laser reflection when cutting overhangs. #Honeycomb Bed

Laser Focus

The focal length of a laser determines the optimum distance of the workpiece from the laser head. A focused laser results in quick cutting speed with a good surface finish. Sub-surface laser engraving is a technique used to make engravings inside the material without affecting the outer surface. A larger focal length is used for laser cutting and a shorter focal length for laser engraving. The advantage of focused laser cutting is that the surface can be made perfectly flat, and there are no distortions in the substrate.

Exhaust System

Although laser-cutting acrylic does not normally emit poisonous gases, it may have a negative impact on your health in the long term. If you use this material a lot, it is necessary to work with a mask so that you will not get asthma or respiratory problems later on.

As a result, it is advised to operate the laser cutter in a well-ventilated location with a dedicated exhaust system.

.jpg)