Since its invention in the 1930s, acrylic or plexiglass has developed so rapidly that today it is unimaginable that it is indispensable in many areas of daily life. This synthetic thermoplastic material is reminiscent of ordinary glass in appearance and feel, but is much easier to process than real glass, especially with a laser machine.

Applications For Cutting Acrylic Glass

Since acrylic glass is transparent, depending on its thickness, very stable and easy to transport, the plastic is suitable as an alternative to glass and can be used as a material for many projects in the public and private sectors.

Popular Uses For Cut Acrylic Glass Are:

- Illuminated advertising and neon advertising

- Signs and lettering

- Sales displays

- Wall coverings

- Architectural models

- Trophies

- and many other plastic products

Acrylic Glass Engraving Applications

In addition to Plexiglas or acrylic glass cutting, we also offer acrylic / Plexiglas engraving.

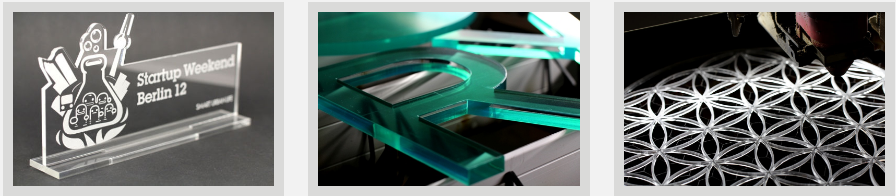

Thanks to modern laser engraver, we can perfectly depict the finest geometric lines and shapes as well as photographs and logos on acrylic. Combined with crystal clear, flame-polished internal contours, this creates a wide range of options for designing products.

Engraved Acrylic Works

- Acrylic trophies with individual engraving

- Unique trophies previously cut to the desired shape

- Advertising logos with personal lettering

- Personalization of promotional items with logos and/or company slogans

Laser engraved processing is most often used in the advertising and signage industry, where we create logos, texts and graphics in clear, tinted, textured or mirrored acrylic.

Materials Used To Cut Acrylic Glass And Engrave Acrylic Glass

Most users want to engrave clear Plexiglas. These materials are particularly suitable for making signs and plaques and are outdoor resistant. With these materials, very different color combinations can be achieved, and even metal and wood looks with deep colored engraving can be used.

How It Works With Laser Engraving And Laser Cutting Machine Of Acrylic

During the laser cutting process, the acrylic is heated at specific points and the heat generated is dissipated directly through the acrylic that is evaporating. This creates crystal clear cut edges and internal contours with no smoke traces or additional post-processing of the material. This eliminates the need for expensive and time-consuming manual flame polishing of cut and milled edges. This makes acrylic/plexiglass cutting less expensive than other methods. With the Sculpfun S10 laser engraving machine, we can cut acrylic sheets up to 15 mm thick. Even the Sculpfun S9 with only 5W optical power can cut acrylic up to 10mm thick, so I have to say that the Sculpfun laser engraver machine is really powerful!

With Plexiglas engraving, the acrylic surface is removed with the help of the laser. In this way, even the finest details can be displayed precisely. The result on transparent plastic is a matte white engraving.

Advantages Of Acrylic Laser Engraving And Laser Cutting

- Clean and chip-free processing

- No post-processing required compared to milling, drilling, and sawing

- Polished cut edges also with gold and silver wire profile

- Radius-free laser cutting of inner contours for all acrylic glass thicknesses

- Combination of laser cutting and laser engraving for complete ownership of your own design

- Standard items are quickly and easily personalized

This is the way to make unique (promotional) gifts, compared to printing, laser engraving is permanent.

.jpg)