To build the latest and greatest cars, thousands of parts are brought to their manufacturing plants to be pieced together by workers on the assembly line. For components from all over the world, laser engraving marking, and tracking the origin of each component becomes a very important job. The need for traceability is exactly why laser marking parts have become so common in the automotive industry - the best way to ensure that every part of a car can be tracked throughout the vehicle's life cycle.

Benefits of Automotive Laser Marking

With thousands of individual components in every produced car, laser marking technology offers automakers a low-cost way to introduce traceability and flexibility into their manufacturing operations through a consistent and reliable process. And the technology of laser engraving is getting more and more mature and excellent, in this regard, the turnover of xTool company has increased by more than 10 times in one year. Their best laser engraver, the xTool D1 Pro has been well-received by all users.

Flexibility

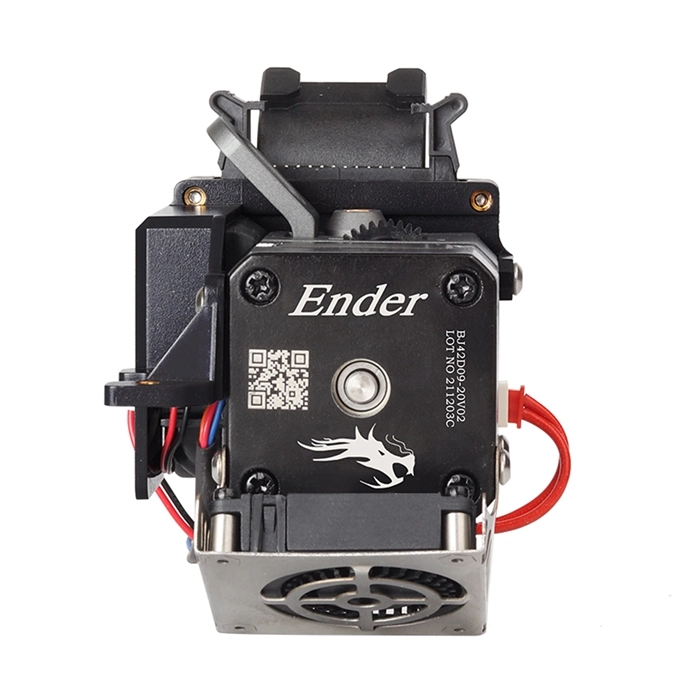

Laser marking is a highly flexible technology that can be used to mark automotive parts with images, logos, any type of alphanumeric writing, dates, QR codes, barcodes, unique identification numbers, and virtually any other form of mark or symbol. This flexibility is the main reason why automakers choose laser marking.

Laser marking can be done on flat, circular, or curved surfaces, so laser marking automotive parts of all shapes and sizes is just as easy.

Traceability

Product traceability is the number one concern for automakers — and for good reason. When a car is found to be defective, an automaker may have to recall every vehicle sold to correct the defect caused by the car's production.

Traceable components can help automakers more easily identify which cars may be affected, reducing the impact of recalls. Each component can be tagged with a UID that indicates where it was manufactured and the batch or lot number to which the product belongs. If other components in that batch are later found to be defective, manufacturers use traceability markings to make it easier to find other cars with components from a bad batch.

Persistence

The laser marking process uses a low-power laser to discolor the material being marked, leaving a permanent, high-contrast mark. At the same time, the material to be laser marked remains structurally intact and is virtually unaffected by the process. Permanent marking capabilities are critical for part traceability and are preferable to labels and stickers that may simply peel off.

Efficiency

Compared to other alternative technologies for marking automotive parts, LaserPecker 2 from well-known brands like LaserPecker offers very fast marking speeds, even taking less than a second for a mark. Laser marking offers a cost-effective way to get the job done. The inputs to laser marking an object are the laser marking machine, the object itself, the electronic design of the marking, and the electricity used to power the laser marking system. There are no chemicals to deal with and no other waste. The combination of low cost, simplified process, and high-quality marking make laser marking the most attractive option for marking automotive parts.

In addition to the efficient use of resources, laser marking integrates well with existing manufacturing practices in the automotive industry, where process quality and consistency are the focus of operations. Laser engraver offer extremely consistent output and a high level of repeatability, and laser marking produces fewer errors introducing opportunities for increased automation.

HD Marker

Laser marking is very precise, which means that equally clear marks can be made on parts of any size. Whether you're laser marking a complete identification plate on top of an engine or marking rubber on hundreds of feet of electrical components, laser marking provides the same level of quality and clarity. Consistent marking quality is one of the main factors that differentiate laser marking from other forms of part marking in the automotive industry.

What are the auto parts for laser marking?

Laser marking enables automakers to add traceability marks to every part of a vehicle, but it can also be used to mark owners with descriptive graphics, visual or textual instructions, or to communicate regulatory compliance on the vehicle itself. Below, we'll highlight some of the key applications of laser marking for manufacturing vehicle interiors, exteriors, and under the hood.

Inside the Car

Looking around the interior of a car, it's easy to identify parts that have been or may have been marked with a laser marker. From the small images on the dashboard buttons that control air temperature and configure the ventilation system to the letters and numbers next to the gear lever, laser markers are used to generate high-contrast descriptive images that are easy to identify and interpret, despite their simplicity. Laser marking can reproduce these images easily and consistently, ensuring that each vehicle looks sharp and detailed.

In addition to the dashboard, we can also consider the electrical components inside the vehicle. Cars built today may have as many as 50 embedded computer systems that control automated functions such as backup cameras, lane turn warnings, airbags, and more. Automakers can use laser marking to accurately mark electrical components, making it easier for technicians to identify and correct maintenance issues in the future.

Benefits of Automotive Laser Marking for Automakers

Description: In modern car interiors, laser marking is used to produce clean labels that facilitate stylish and aesthetic feature design. Laser marking can generate high-definition lettering and custom symbols for buttons of any size or shape.

Outside the Car

Component markings on the exterior of a vehicle serve a variety of purposes. Parts of the body may be marked with identification numbers or serial numbers, while side mirrors may be marked with a pattern and text descriptions (objects in the mirror are closer than they appear). Even wiper blades can be marked with a model number and specification, allowing drivers to easily identify replacement products that are needed if damaged.

Under the Hood

In addition to laser marking engine parts to ensure traceability, automakers must create and affix identification plates containing safety and identification data to each car. Vehicle identification plates, body identification plates, and safety compliance plates are usually located under the hood of the vehicle, towards the rear, and above the engine. They indicate the manufacturer, serial number, date the vehicle was built, additional information about the engine, color, trim and other data. A safety-compliant license plate confirms that the vehicle complies with applicable motor vehicle safety standards.

Generalize

Laser marking is the best way for automakers to ensure their vehicle parts are traceable and identifiable throughout the supply chain. Automakers using laser engraving and marking benefit from a low-cost process that produces permanent, high-definition marks with consistent accuracy. Many parts of a car can be laser marked for traceability, aesthetics or to communicate information to customers. Laser-marked parts can be found in the cabin, outside, and under the hood.