Previously, laser engraving was only used by industrial companies to identify parts and tools, or by shops to customize prizes and trophies. Today, however, there are a large number of small companies that specialize in cutting or labeling products. Laser engraving has now developed into a lucrative industry and the corresponding equipment has become very cheap.

The Sculpfun laser engraver market has grown significantly over the past five years. According to market research firm IBIS World, the compound annual growth rate in 2016 was 5.5%. The growth was driven by increased demand for customized products such as smartphones, tablets and tableware, as well as items made from wood, metal and other materials. In addition, companies use laser engraver for internal tasks, eg. B. Promotions and incentives designed for employees and signage for your own premises.

As laser engraving machines become cheaper and more accessible, device sales and shipments are expected to continue to grow over the next five years.

There are other factors contributing to the growth of the laser engraving industry, from growing interest in personalization and easier access to laser equipment, to the manufacturer scene, branding, and new uses for laser engraving.

Factor 1: Personalization Is Increasingly Important

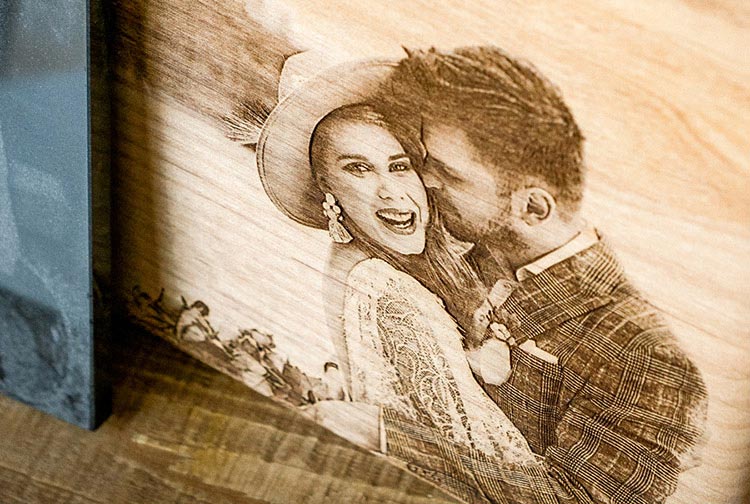

Using a laser engraving service e-commerce platform, it is easy to understand the growing popularity of laser engraving in recent years. Personalization turns simple objects like champagne glasses into personal gifts with personal meaning.

A search for the term "laser engraving" on the service platform will reveal a wide variety of custom product listings including jewelry, wedding glasses, craft supplies, bags and wallets, computer accessories, personalized dog collars and labels, woodwork, beer mugs, pens , tools, golf tees, etc.

Sculpfun S10 laser engraving is also used in millions of electronic devices that have been produced and sold to give them a personalized touch. A single item stands out from a multitude of products by engraving a single graphic, logo or name on an electronic device.

Factor 2: Higher Availability

Laser engraving and laser cutting systems have been difficult to obtain in the past. Supply is limited, and importantly, the initial cost of equipment is beyond the capabilities of private vendors and small businesses interested in the technology.

Today, laser engraving is no longer just affordable for big companies. Many potential buyers don't even know how cheap these devices are getting. Whether buying, renting or renting, laser equipment that meets the buyer's individual requirements is available in many locations around the world. Sculpfun S30 Pro Max laser engravers and laser cutters are available from HTPOW, and universities and other educational institutions can search for specific systems in their area.

With this ready availability, laser engravers are now used in corporate and school labs, maker spaces, and many other educational institutions and small businesses to customize and manufacture products.

Factor 3: The Maker Movement

With more and more people getting excited about customizing things, the number of manufacturers is increasing every day. Under the do-it-yourself slogan, many interested are learning new skills, designing products or discovering cost-saving opportunities on projects that have been outsourced in the past.

Laser engraving also plays an important role here. Recently, HTPOW participated in the Maker Faire Bay Area. Hobbyists have a keen interest in the possibilities of laser technology. Whether prototyping, decorative engraving or starting a company for personal engraving: with laser engraving and laser cutting, ideas become products.

Factor 4: Dissemination In The Industrial Sector

There are signs that laser engraving is increasingly being used in industrial technology applications. The technology is ideal for credit cards, ID cards, confidential documents and other objects that require enhanced security measures. There are also signs that the field of safety marking is one of the most important segments of laser Engraving.

Laser engraving can permanently mark objects for better detection of counterfeits and imitations. Multi-layer format is used in ID cards to change the color of the underlying paint without affecting the transparent top layer. In this way, products with high image and text quality are protected against fraud and manipulation.Laser devices allow etching/engraving of serial numbers, time stamps, part numbers, component boards, date codes, barcodes, and industry specific codes. It's no surprise that laser engraver has become so important in parts identification, inventory control and monitoring, safety and warning labels, and damage prevention.

As technology advances, future application areas for laser engraving may lie in robotics, 3D printing, and the automotive industry.

Factor 5: Communication In The Brand Field

Laser engraving machine is an effective deterrent against product and property theft. Stolen items with prominent logos or company names are difficult to resell. Engraved barcodes or serial numbers are an extension of a company's brand, and can be easily traced by the company.

Factor 6: Low Prices

Prices for laser engraving and laser cutting machine remain stable despite increased demand, according to the American Laser Manufacturers Association (ALMA). Purchasing a laser engraving machine is extremely cost-effective compared to buying a high-power, high-quality machine, ALMA says.

Factor 7: More Accessories

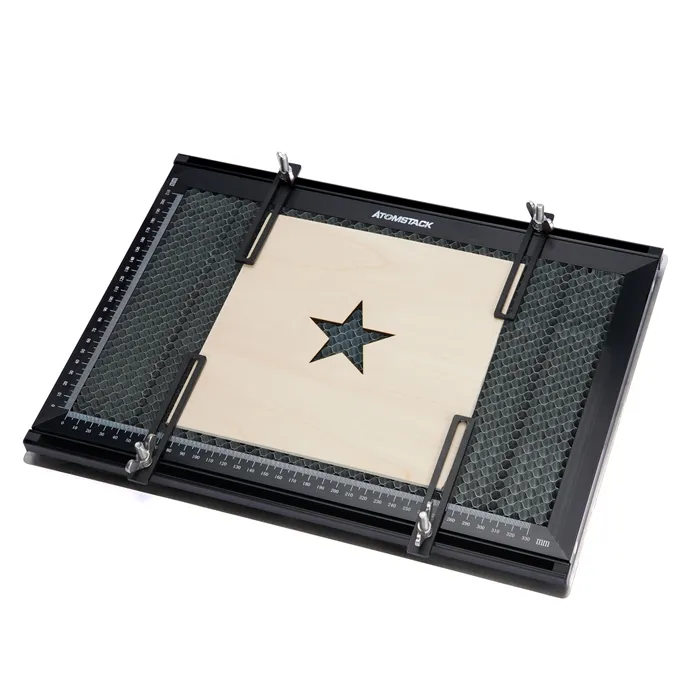

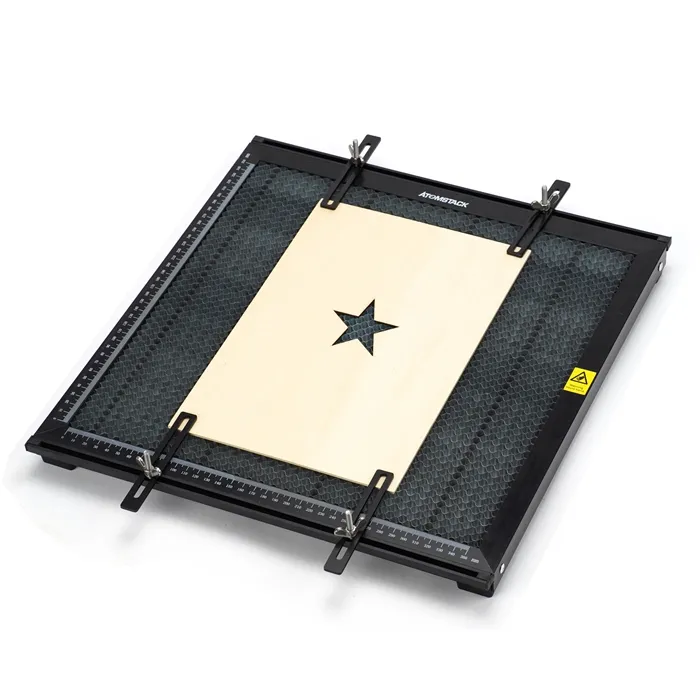

Advances in laser cutting and engraving have led to the development of new accessories that allow for more and improved applications. These include sculpfun laser rotary roller, professional lenses, air compressors, pen holders and photo manipulation software.

Factor 8: New and Different Markets for Laser EngravingNew market segments are gradually embracing laser engraving. These include woodworking and metalworking, digital and retail signage, model making, clothing and textile stores, gadgets and sports equipment. One of the reasons for the future surge in laser engraving machines is that they can target a wide range of industries.

These eight factors help ensure that the development of the laser engraving and cutting market shows no signs of slowing down after the impressive growth of the past five years.