Laser Cutter Ventilation System: Removal of Laser Cutter Odors and Fumes

Setting up your laser exhaust system is critical to your health and that of your laser engraver. Without an effective exhaust system, the air quality in your workplace will immediately drop, odors will start to collect and fill your home, and medical problems can be exacerbated. Depending on the material you use the laser for, laser cutter odors and toxic fumes can enter your lungs, causing illness, suffocation, or even death. While the Ortur Laser Master 3 lasers are beginner friendly and can be placed in your home, never forget: these are industrial grade lasers with a variety of hazards and safety must always be your top priority. If you want to start your laser creativity, then you can go to the HTPOW online store to choose your favorite laser engraving machine.

The best laser engraved exhaust system is one that quickly removes all fumes and odors outside, operates quietly, and poses no danger to neighbors or second-floor residents. A proper laser cutter ventilation system is also important, as fumes trapped inside the machine can stain mirrors and focusing lenses and cause optical damage.

In this article, I'll teach you how to set up a laser exhaust system and give you some examples of different setups so you can find the one that works best for you. Whether you're working in a garage, an insulated shed, or a room in your home, having an effective laser exhaust system is vital to your DIY laser project, your health, and your laser machine.

Before you set up your exhaust system and start testing your new Ortur Laser Master 3 laser engraver, be sure to set up your laser workshop and download your manual.

Review the user manual for safety information and follow the installation instructions as well as the instructions in the installation guide and this article.

Comply with all laws and local regulations regarding the safe discharge of specific engraving materials.

Vocabulary Check: Laser Engraver Exhaust System

Before we help you understand how to set up a laser exhaust system, check out these important laser engraving terms:

Laser Exhaust System - The exhaust system is responsible for removing engraving debris (gas, fumes, fumes and airborne particles). The system consists of a number of separate components, including (but not limited to):

Exhaust Port - The physical exhaust port where the laser exhaust exits the building or structure.

Exhaust Port - The physical port located on the laser engraver where exhaust air will be expelled from the machine. Note that the 130W and 150W machines have two exhaust ports.

Internal Fan – The built-in exhaust fan inside the laser, located at the exhaust output port. This fan extracts gas and airborne debris from the bench, ducting it out of a vent or fume extractor.

Inline Fan - The Inline Exhaust Fan for the Laser Cutter is a separately purchased accessory that is added to the Laser Exhaust System to help with smoke extraction. To maximize efficiency, it is installed as close to the exhaust as possible.

Exhaust Tube – The physical hose that connects the laser exhaust output port to the inline fan or exhaust.

Fume Extractor — An external machine that draws in dirty air, passes it through a series of filters to remove debris, and releases clean, healthy air back into the same room. Laser-cut fume extractors are necessary for narrow work spaces without exhaust vents.

Planning your laser exhaust system

If you've already purchased a laser, you probably know exactly where to put it. If you don't, these instructions will help you weigh your options.

You need to place the laser engraver as close to the exhaust as possible. Many laser engraver users simply use windows or doors as exhaust vents. For some people, an existing hole in the wall, such as a dryer vent, is a perfect fit.

You need to keep the number of corners or "bends" to an absolute minimum and minimize the length of tubing between the laser and the exhaust. This will help reduce airflow and stress - if polluted air and odors travel less distance, they will be expelled from your workspace faster. The laser cutter exhaust fan inside moves far less air, helping it function better and removing the laser cutter smell before it reaches your nose.

Take note of your laser workspace and ask yourself some of these questions.

Where is your laser engraver?

- Residential or industrial workplace

- Garage

- Basement

- Dedicated workshop

- Climate control shed

- Bedroom or office

- Apartment

- House or apartment

Find the right laser vent:

- Is there a window I can use to ventilate my laser machine?

- Can I open a window, door or garage every time I run the laser engraver?

- Can I drill a hole in the wall?

- Is the neighbor too close to my laser exhaust?

- Is there a second floor room above my laser cutter exhaust?

- Are there air conditioning units or other intakes near my exhaust that can draw exhaust back into my building or an adjacent building?

- Now that you've had time to think about it, here are some options for your laser cutter ventilation system, depending on your workshop.

How to Set Up a Laser Engraved Exhaust System

This Laser Engraver Exhaust System Setup Guide is intended to complement the Ortur Laser 3 manual, review the complete manual before beginning setup.

Standard setting - exhaust air to outside through windows or doors

If you have a window near your laser, you can actually measure the opening and then use your laser to cut a hole to fit the size of the pipe you have. You will need to find a way to seal it properly, especially if you live in a cooler climate. In this case, you may need some kind of foam insulation board to keep cold air out.

Another option is that you can actually buy an adjustable window dryer vent if you choose to ventilate from a window. This useful vent will fit into your window frame and act as a temporary (or permanent) vent. Plus, you can take it off and close the window when you're done working. To start setting up your laser engraver exhaust system,

Laser Vent Window Vent for Laser Cutting Machines

Last but not least, if your laser is near the door, you can simply stick the tube out of the door. This might be ok in the short term, but opening the door again could lead to some unwanted downfalls, such as the possibility of wild animals entering your workshop. Not to mention, it's less than ideal in cooler weather, unless it's hot in your area.

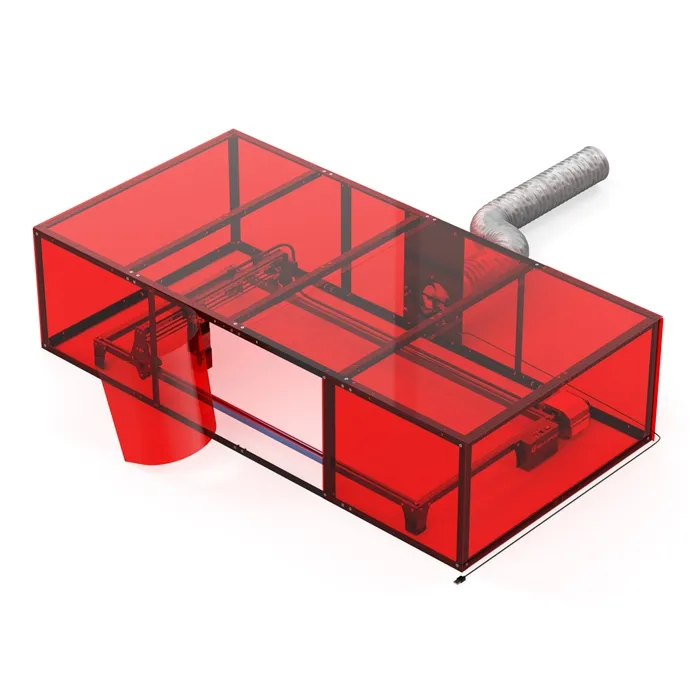

Ortur's DIY Laser Cutter Ventilation System

Laser Exhaust Outlet Garage Door Laser Cutter Ventilation System

Ortur users simply open the garage door and place the exhaust pipe underneath. He's currently working on improving his workspace, so this is a great solution for him to work on until the ideal laser exhaust is done.

Laser exhaust vents through the wall to the outside

If you don't have a window or door near your machine, the next option to consider is to drill a hole to let the exhaust air out. This option is more suitable for homeowners who have more experience with building structures.

There are several factors to consider, depending on your location. Wiring and plumbing run through the wall, so you need to make sure the wall area is safe for cuts. You can use some special detection equipment to alert you. Professional stud detectors are also available, as some can visibly detect metal in wires and pipes. Once you've confirmed that the area is safe to cut, you'll need a tool to drill and cut a hole in the wall.

In my case, my dad was familiar with building our house and my brother was an electrician, so tailoring was probably easier for us than others. He ended up using an auger bit to cut the hole.

"The laser cutter ventilation system I have now is a 6" duct that runs from the side of my home with a dryer vent. I use an AC Infinity 6" inline fan for the laser cutter. It's fixed Machine with heavy duty magnets on the side. If I were to do it again, I would move the fan closer to the exhaust point. I just haven't had time to do it yet. Ortur user and demo room host

Laser fume extractor

Finally, one of the more expensive options is to buy a laser fume extractor for laser cutting. Getting outside for ventilation may not always be an option, so if you find yourself in one of these situations and looking to buy a laser machine, it's important to remember that a laser-cut fume extractor can be an expensive add-on.

For those who work in confined spaces and cannot use windows, doors, or cut holes in walls, the laser cutter's dedicated fume extractor allows you to use the laser safely indoors.

Laser fume extractor for laser engraving and cutting machine

What is a laser smoke evacuator?

A laser fume extractor is like a vacuum cleaner attached to a laser exhaust filter that removes particles from the air - it draws in dirty air, removes debris through a series of specialized filters, and then removes clean, healthy air Release back to the same room.

Laser Smoke Extractor Laser Exhaust Filter

Laser cutting fume extractors come in different sizes, depending on the size of the laser machine table. If you use the laser a lot, you will need to replace the cartridges and filters to maintain it. You also need to check the shelf life of the filter you are using. Some may need to be replaced every thirty days, while others may be replaced every six months, depending on your usage. There are also various ways to make a DIY laser exhaust filter or DIY smoke evacuator, but these can create a breathing hazard in your work area.

Laser fume extractor for laser cutting engraving machine

If you're looking for a laser smoke extractor, the Ortur Master 3 actually has a lot of options. Make sure you are looking for equipment that is compatible with your laser machine. The fume extractor's hose should be connected directly to the laser where you normally run the exhaust.

Additional Laser Exhaust System Tips

Now that we've listed the different options available for laser exhaust, let's talk about some other great tips that should be considered.

Seal every seam and joint in metal piping to eliminate air leaks. You can use a caulk-like sealant or special aluminum tape, both of which are available at your local hardware store (usually found near plumbing equipment). A good sealant will harden and remain flexible, creating a reliable seal. Tape around each seam, connection point, and elbow.

Intake - The air leaving the room must be replaced with fresh air (also called make-up air) entering the room. On your machine, you can open the front pass-through door to create additional air intakes. Also, make sure there is a second open window or door (besides the exhaust) to let air into the room.

Hopefully this article helps shed light on why not only is it important to have a working laser engraver exhaust system, but how to design an efficient laser exhaust system. Make sure you are always aware of your surroundings. Fumes from laser exhaust are dangerous - never ignore strange smells, and be sure to seek fresh air quickly if you think your health is in immediate danger. If there is an odor, remember to open the window and turn on the fan.