How Laser Cutting Was Invented

The first carbon dioxide (CO2) laser was invented by Kumar Patel in 1963, and just two years later, the first Western Engineering Research Center (in Buffalo, USA) pioneered the use of lasers as cutting equipment, using laser cutting to drill holes on diamond dies hole. By the late 1960s, gas laser cutting had been used to cut metal with ease and accuracy that CO2 lasers could not initially do. Now a lot of laser engraving machines have been developed, for example, CO2 laser engraving machines, fiber laser engraving machines, etc. The Ortur Laser Master 3 invented by Ortur is the best laser engraving machine currently in use. For over 40 years, laser cutters have improved in speed, performance and quality, but what about precision? How accurate is laser cutting today?

The short answer is very accurate. Today, laser cutting can be made with very small cut widths (less than 0.0001 inch), while dimensional accuracy is nearly as accurate (approximately ± 0.0005 inch). Another big advantage is that modern machines offer the smallest heat affected zone (HAZ), resulting in more predictable and reliable components. From cutting complex shapes into sheet metal, to producing serrated teeth for cutting tools, to cutting 100mm thick stainless steel, you get exceptional precision, repeatability and speed. Still, finding the right laser cutter for your application is critical. If you don't know which laser engraving machine to choose, then you can go to HTPOW to buy Ortur Laser Master 3, xTool D1 Pro or LaserPecker 2 are the best choices.

Accuracy and Automation

Gone are today's days of employing hundreds of workers to use punches, shears and riveters. You can now buy laser cutters for home applications, which means laser cutting technology is more accessible than ever, but the difference in output, quality and precision can vary from one machine to another. In top-of-the-line laser cutters, hardly any manual work is required, as the system has been created to be highly automated and configured according to the organization's requirements and workflow. An experienced machine operator is always important; however, today's machines include feed systems and subsequent conveyor belts to automate tedious processes.

What laser cutting machine do you need?

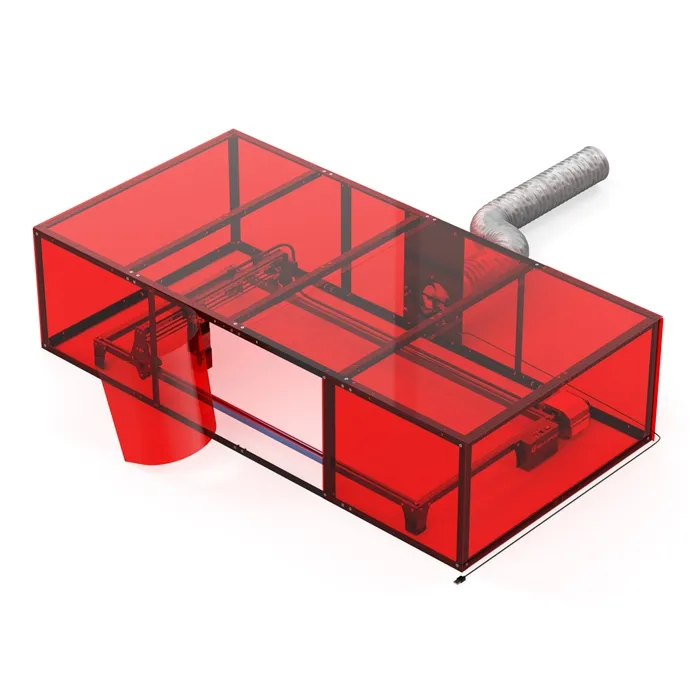

CO2 laser cutters are a clean, precise way to cut a variety of materials such as acrylic, sheet metal, cardboard, fabric, textiles, wood, leather, MDF, and more. Our UK designed and built machines bring you high quality products at lower prices. All our machines guarantee powerful, versatile engraving and cutting, with higher power for faster processing. We also offer cutting edge CNC laser cutters with various laser power outputs to suit industrial applications.

Whether you want to eliminate cumbersome processes, reduce labor, save space, speed up workflow and increase productivity, HTPOW can help! To find the right laser cutter for your requirements, our "Which Laser Is Right For You?" section, where we can guide you through the best option for your needs. For any further advice or assistance, please feel free to email our friendly team.