Zero Width Laser Cutting Technology™ is a method and process for cutting glass and other brittle non-metallic materials. The process splits the material at the molecular level in a non-contact process at a very fast rate without causing material loss, chips, transverse cracks, protrusions, hooks and flares, or any other form of contamination. It is mainly used in laser engraver.

What is Zero-Width Laser Cutting?

The technology uses a laser-controlled power density distribution on the material surface to generate greater subsurface forces than intermolecular connections. This technology significantly improves the substrate separation process and is particularly suited for the latest generation (6th, 7th and 8th generation) glass panels used in flat panel display (FPD) manufacturing. The zero-width laser cutting technology has been optimized for thin glass applications up to 1.0 mm, but can be applied to other thicknesses as well. Home laser drops can generally not achieve this kind of precision, for example the Ortur Laser Master 3 has a minimum engraving accuracy of 0.01 mm, but it is possible to achieve very fine engraving results.

The method uses non-contact laser-induced internal stress to produce controlled separation. Because the technique is non-contact, surface degradation associated with mechanical scribing and fracture is eliminated. Yield loss due to particle damage is also greatly reduced. Cutting substrates under cleanroom conditions becomes feasible using zero-width laser cutting technology, enabling the introduction of the production line concept to cleanroom substrate manufacturing. This was previously not possible because debris was generated during the cutting and grinding process, which is not generated during the zero-width laser cutting technology process. In addition, cleaning facilities can be significantly reduced. These factors provide a cost effective solution for manufacturing space and efficiency. Systems utilizing zero-width laser cutting technology can penetrate more deeply into precisely controlled microcracks. The process creates high-speed scribes (up to 1 meter per second, depending on material type and thickness) in a pre-arranged manner, with no molecules leaving the surface, significantly improving the substrate separation process.

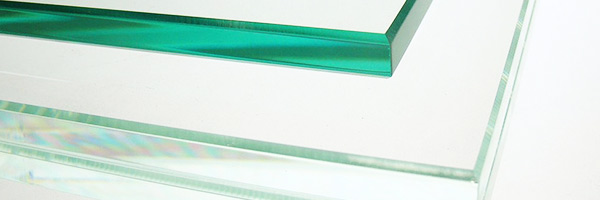

The zero-width laser cutting technique method incorporates cooling of the glass surface after controlled heating with the correct power density distribution, which allows intermolecular separation of the glass substrate to a certain depth. Assuming a constant power (P), the depth (t) is inversely related to the cutting speed (v). This means that the slower the speed, the deeper the separation formed. Both mathematical models and empirical data support these findings, and field experience validates these findings. Zero-width laser cutting technology is the only dimensionless cutting line technology available in the world. Unlike conventional methods, such as those involving diamond blades, the scrap generated during the cutting process can be completely eliminated.

Yesterday's solution: inaccurate, wasteful cutting with diamond blades

Zero-width laser cutting technology was previously licensed to glass manufacturing companies worldwide. These license agreements have expired, and as of this writing, very few companies have been licensed to use the technology. Zero-width laser cutting technology is currently available for laser photonic systems.

About HTPOW

HTPOW has cooperated with almost laser engraving and cutting machine brands and has become the world's largest supplier of home laser engraving machines. You can have a lot of choices, and the laser engraving machines are all very capable, but at a very cost effective price.