There are many people who have misconceptions about laser engraver, especially regarding the shape of the product to be marked. A common problem is that marking systems are only available for flat products. This is not true. Many marking systems are available for many shapes and sizes. For example, the LaserPecker 2 can mark items at an engraving speed of 36,000 mm/min.

Laser engraver available for round products.

Marking System 1: Scribing

Scribing cylindrical objects Scribing is a part marking process that involves removing material from the product by dragging a stylus. This creates a smooth continuous mark, deep and permanent, and is the perfect marking process for achieving high quality marks and low noise during production. You can use an Ortur Laser Master 3 to retain a beautiful laser mark on the item.

Scribing is suitable for round or cylindrical products as it provides greater freedom for the operator. However, it does not provide contrast, so it is less suitable if contrast is a desired attribute.

Marking System 2: Rolling Marker

Roll marking is the most common laser marking system for large cylindrical objects, such as gas cylinders, pipes and tubes. It consists of mounting a roll die containing an inscription marked on a lathe and pressing it onto the part. Roll marking is suitable for this process because.

It does not subject the gas cylinder to thermal and chemical stresses

Although it is not hand-held, it can easily mark round and cylindrical products, regardless of their construction

It is suitable for any size object

Although efficient, the process has the same drawbacks as scribing and spot spraying. That is, it produces a highly readable image, but without contrast.

Marking System 3: Dot Peening

Dot peen is a common marking system for round products such as gas cylinders. It involves the use of a pneumatically or electrically controlled needle or stylus to strike the part and mark it. The markings are readable and permanent, and the part is not subject to thermal or chemical stresses. However, just like scribing, there is no contrast, reducing clarity and generating a lot of noise.

Spot blasting is a highly rated marking system for round and cylindrical bodies. Portable spot blasting machines such as LaserPecker 3 and are the best choice for large objects. These machines allow the operator greater freedom. Benchtop spot blasting machines are a better choice for smaller parts.

Software inclusion further makes the spot blast marking system a favorite of manufacturers who make round objects. The software allows the operator to store codes, which is different from scribing, where everything is mechanical.

Marking System 4: Laser Marking

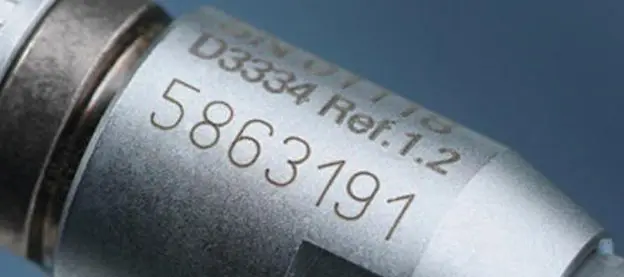

Laser Marking of Cylindrical Objects Laser marking is the most popular marking system that provides permanent and readable marks on any product. It involves the use of a laser beam to mark the object.

Laser marking includes various techniques such as engraving, etching, annealing and ablation. Each is suitable for marking round and cylindrical objects, depending on the material you want to mark.

Portable laser markers are best suited for round and cylindrical objects because they offer a great deal of freedom. However, when considering efficiency, you may want to consider the power level and the type of material being used.

In terms of material compatibility, laser engravers such as the xTool D1 Pro, Ortur Laser Master 3, and others can mark different types of metal materials, while CO2 laser markers such as the HS-CL20 are suitable for organic materials such as non-metals.

Marking System 5: Inkjet Marking

Inkjet marking involves the use of a nozzle to deposit ink on a material to mark it. The two main types are continuous marking and inkjet-on-demand (DOD) marking. Inkjet markers provide highly readable markings. However, they are not permanent most of the time.

How to choose the right marking machine for round and cylindrical products?

A successful marking process depends on the method and machine used. Therefore, it is crucial to understand several factors that play an important role in choosing the right method and machine.

-What is Your Budget?

Your budget is the backbone of your decision. However, you should choose a machine/method that provides effective and efficient marking while fitting into your budget.

-What is The Size of The Round Object?

Another factor that will determine your choice of marking machine is the size. Some machines are better suited for large round and cylindrical objects. For example, rolling markers. On the other hand, some are more suitable for smaller ones. There are others, such as laser marking, that can efficiently mark round objects of different sizes.

-Machine Portability

Handheld machines are easier to handle and manipulate, making them ideal for large cylindrical objects. There are several types depending on the marking system. However, consider a marking machine with industrial capabilities. Handheld machines from different marking systems are suitable for large objects.

-Material Selection

Each marking system has its own material compatibility. Rolling marking is suitable for metal and precision systems. For example, it is widely used for marking gas cylinders. Dot peen marking is suitable for metals or materials that are subject to mechanical stress.

-Marking Durability and Readability

If readability is important, laser markers and inkjet marking are the best choice. These marking systems help improve readability by creating contrast between the part and the mark. While marking systems other than inkjet marking offer permanent marking, laser marking systems are the only systems that offer permanent and readable marking.

How to Get The Best Round and Cylindrical Laser Engravers

Marking cylinders may be for identification or traceability purposes. Therefore, you should use the best marking machine and method. This article describes the different machines and methods you can use and how to choose them. htpow is the most professional laser engraving machine service provider in the market. Come and enjoy first-class services that put customer satisfaction first.