When people talk about laser engraving, most of the time that comes to their minds is 2D laser marking. Today, however, 3D laser marking is becoming more and more common to mark 3D pictures, names, etc. on products and materials due to the depth introduced into the marking and the accuracy, precision and speed of the process. How it works, its advantages, the machines you can use, and many more industrial applications.

What is 3D Marking?

Before discussing 3D laser marking, it is important to understand the concept of "3D marking" and the difference between 2D marking.

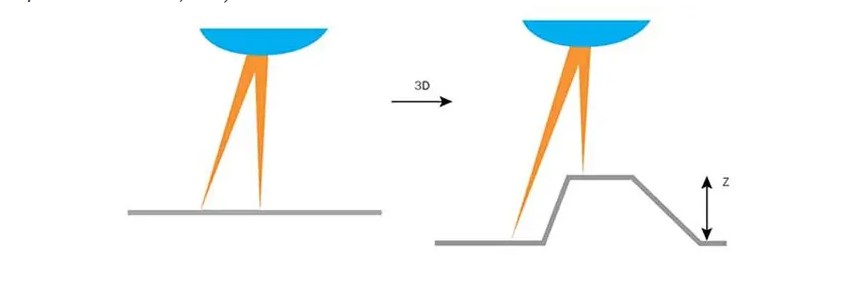

On the one hand, the two-dimensional marks have different widths, lengths and constant depths. So whenever you look at them they look flat. 3D markers, on the other hand, have different widths, lengths, and heights. Therefore, it can be said that they are 2D markers with different heights.

In addition, the variation in height makes the process suitable for marking products of different shapes, such as tapered products, indentations, etc.

How does 3D Laser Marking Work?

The procedure surrounding marking with a 3D laser depends on the chosen laser technology. The most common process is 3D laser engraving. The effect of engraving a 3D pattern is achieved by adjusting the laser intensity, etc. The following steps show how the process works.

·Design 3D laser marking

Design markers as photos or text and model them into 3D designs using computer software such as Adobe and Autodesk. Make sure to define the dimensions correctly for accurate marking.

·Marking

Choose 3D laser marking machine according to material, speed, power, etc. The general mechanism of a 3D laser machine is to mark a workpiece by drawing some points in the 3D design of the workpiece. After that, the machine performs high power (dark tinting) and low power (low tinting) inclusions according to the height definition of the design until the marking process is complete.

· Post mark

The post-marking process is workpiece dependent and involves cleaning the surface of the material after engraving. Also, some machines do not require post-marking due to the presence of the fume extractor.

Why is 3D Laser Marking Important?

3D laser marking is as important as 2D laser marking in industry and commerce. Here are some of the importance of the process above 2D markers.

· Very flexible

3D laser marking is more flexible for different surfaces and shapes. For example, you can use it to mark products with round, cylindrical, conical, concave/convex or triangular shapes. This is possible because the 3D laser machine is able to adjust the laser beam position and focus.

·Suitable for deep carving

3D laser machines are also better for deep engraving due to the high degree of control. This is different from 2D laser machines, where the energy can drop dramatically as the laser moves in position, causing the quality of the mark to drop. So you need to set a fixed engraving specificity, which requires the laser engraver machine to have the ability to detect the engraving distance. Of course, this effect cannot be achieved very well now, so LaserPecker 2 provides a protective cover, so that the protective cover is close to the engraving material, This will better sculpt the same effect.

·Multi-Color Markers

3D laser marking machine is more suitable for multi-color marking. Differences in height and laser intensity lead to improvements in polychromatic. This is an important aesthetic parameter that occurs through the process.

· Better Personalization

3D laser marking has better aesthetic value than 2D marking. Markers stand out, making them unique and beautiful. While making 3D markers can be challenging, designers can relax and create the perfect 3D gift.

·Quality Mark

3D laser marking is superior to other 3D marking systems because it provides high quality marks. However, it depends on the type of machine you are using. If you want to know more about the machine, you can contact us.

Materials Suitable for 3D Laser Marking

3D Laser Marking Machine

Unlike 2D laser marking, not all materials are compatible with 3D laser marking. For example, the process is not suitable for stone because of its hardness. If you want to mark the stone, then you can still choose LaserPecker laser engraving machine, which can engrave very well. Here are the best materials for the process

·hardwood

There are the most common 3D laser marking materials. It fits perfectly due to its aesthetics. Although the material is burnt in the process, it is easily cleaned with water.

·Acrylic

This is the second most common material in the process. It is harder than wood. However, it has an impressively good melting point. Therefore, it is capable of 3D laser marking.

· Medium Density Fiberboard (MDF)

MDF is the perfect material if you're looking for material that you can mark and draw later. It's soft, affordable and easy to use.

·Metal

Metals such as aluminum, stainless steel, copper, etc. are also compatible with 3D laser marking. They are the second most common 3D laser marking material.

How to Make 3D Laser Marking Easier

3D laser marking can be a challenge. However, you can use the following methods to simplify the process.

· Buy the Right Laser Machine

Buying the right laser machine is the key to successful 3D laser marking. Machines must be able to interpret shades of color and have fast pulse durations. Also, you have to look at the laser power and other parameters. The price of 3D laser engraving machine is very expensive now. If you want to use a more cost-effective laser engraving machine, then it is recommended that you use a 2D laser engraving machine. I believe LaserPecker Pro 2 is a good choice.

· Get the Right Engraving Depth

Make sure to use the proper depth. It depends on the material you use. For example, wood is easier to mark than other materials. You can ensure you have the proper depth by using design software that you fully understand.

· Artwork Should be Perfectly Designed

Designing the correct markup is the most challenging part of the process. This is time-consuming and mind-consuming. Still, make sure the design is crisp and well-shaded for accurate depth reproduction. Common software includes Photoshop, CorelDraw, and Adobe Illustrator.

· Be Patient

During this process, you need to be patient. The completion time of the process depends on the laser machine, resolution and size.

Get the Best Laser Markers and Laser Accessories

Bringing depth to markup offers designers, manufacturers, and more a way to improve markup for personalization and identification. However, 3D laser marking is not as simple as 2D marking. This article discusses 3D laser marking machines and how the process works. If you want to know more other knowledge, you can also contact HTPOW.