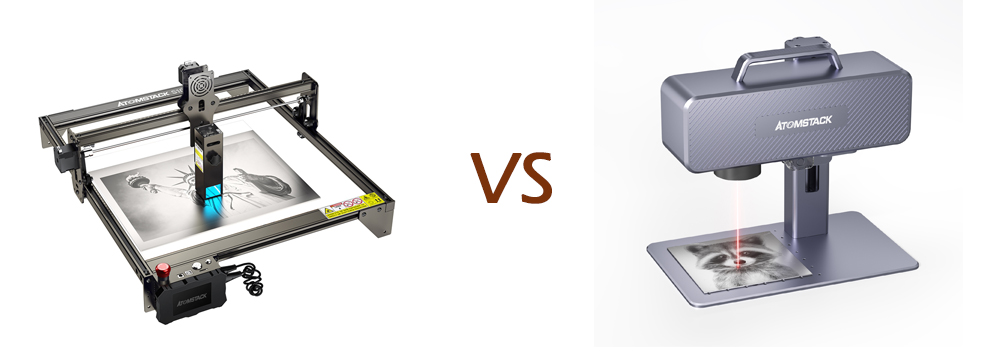

Atomstack m4 20w refers to a device that uses a laser beam to permanently mark the surface of various substances. laser engraver refers to advanced equipment that uses lasers to engrave materials that need to be engraved. The common features of laser marking machines and laser engravers are all processed by laser, and they all belong to advertising equipment. Laser marking machines can be used not only in the advertising industry but also in various packaging industries. laser engravers can be used not only in the advertising industry, but also in various decoration, automobile industries, etc. So, what's the difference between the two?

1. The working principle is different

Laser marking machines use laser beams to make permanent marks on the surface of various materials. The function of marking is to expose the deep material through the evaporation of the surface material, or to "engrave" traces through chemical and physical changes of the surface material caused by light energy, or to burn off part of the material through light energy to display the desired etching pattern and text. .

A laser engraver is a laser device that uses the thermal energy of a laser to engrave and cut materials. Also known as laser cutting machine, laser etching machine, etc.

2. Different lasers are used

The optical path system part of the laser engraver is composed of three reflective lenses and a focusing mirror, and the laser is generally a carbon dioxide glass tube. The life of glass tube lasers is generally within 2000-10000 hours. Carbon dioxide glass tube lasers are all disposable. The lasers of laser marking machines are generally metal tube lasers (non-metal marking machines) and YAG solid-state lasers (metal laser marking machines), and the lifespan is generally more than five years. The metal tube of the laser marking machine can be inflated again for use.

3. The carving area is different

Laser marking machines are generally capable of marking 200*200mm patterns, and engraving machines can engrave large patterns.

4. Different processing speed

The engraving speed of the laser engraver is generally the fastest cutting speed of 200mm/s and the engraving speed of 500mm/s; the speed of the laser marking machine is generally three times that of the laser engraver.

5. Different processing techniques

The laser engraver can be equipped with an electric lifting platform and a rotating shaft, which can engrave regular or irregular objects such as cylinders, special shapes, and spheres. Due to the stability control of the Q head and the optical path setting of the laser marking machine, the platform can adjust the focal length left and right up and down, so it is mostly suitable for plane engraving.

6. Different prices

The price of laser marking machine varies from tens of thousands to hundreds of thousands of corresponding models due to different materials. For non-metallic laser engraving and cutting machines, the price of low power is much cheaper than that of laser marking machines. But laser engravers for cutting thick metals are also expensive.