HTPOW visited some of the more reputable Chinese laser tube manufacturers. I'm sure they indicate a useful life of 1,000 to 10,000 hours. Subsequently, the underwriting period is generally 3 to 12 months. However, if you treat your laser engraver correctly, you can get years of use.

So, how long can a laser tube last in reality? It is generally accepted that CO2 glass laser tubes degrade over time, even when not in use. Fortunately, good grade A tubing does not degrade in this way. Laser engravers from the manufacturer Ortur, for example, use Class A laser tubes and fiber lasers, which means that it is not uncommon for glass CO2 laser tubes to last 3+ years with proper handling and use.

So How to Tell If Your Laser Tube Is Faulty Within The Warranty Period?

Check out Ortur, it's a brand I've used. The laser engraving machine they use claims to last for a long time. They also offer a one-year warranty. There is even a customer Tony in New York State, because he has been using Ortur Laser Master 3 for almost a year, and his laser engraving machine has problems due to the wrong use method, and the customer has done warranty service

Buying laser tubes from reputable sources, you can expect the actual power output of the laser to be around 7~10% higher than the rated value. So a 60 watt tube (physical dimensions are usually about 50mm diameter and 1200mm long) will usually put out about 65 watts when new. The tube needs power output to drop below 45 watts within the first 180 days to claim warranty. Making a claim usually requires video evidence.

It is not uncommon for an A-grade, reputable brand to be used for more than 2-3 years or even longer. But first making sure you have grade A tubes is the main issue.

Problem with Class B Pipes

It is very common for "suppliers" to sell Grade B pipe that does not meet the quality standards required by the manufacturer. Instead of scrapping the tubes, the manufacturer sold them as Grade B to resellers in China.

Low Power Class B Laser Tube

It is not uncommon for resellers to "inflate" power output figures if a tube is rejected for being below the manufacturer's power rating. Failures can be caused by manufacturing defects that also affect tube life. Not surprisingly, the original manufacturer won't support these Class B tubes, and you could be in trouble.

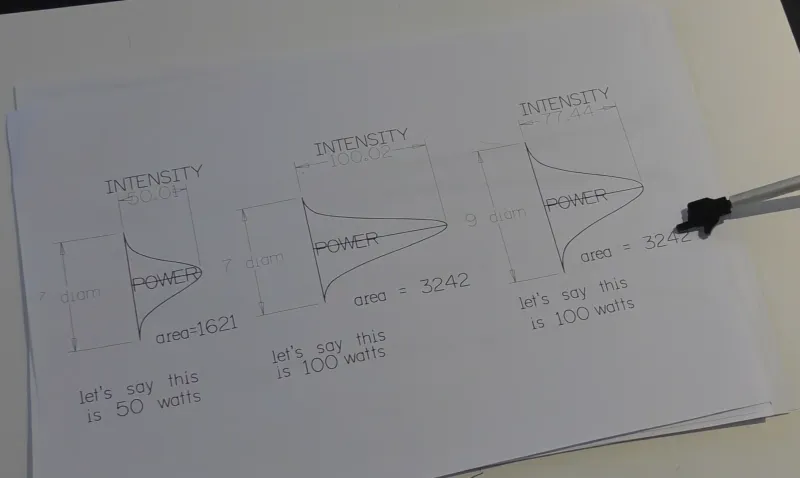

Low Intensity Class B Laser Tube

A more insidious cause of failure could be the intensity of the laser beam. This is insidious because the tube may actually output the specified laser power. However, the lower intensity of the laser beam means that the cutting performance of the tube is poor. A simple analogy is that a sharpened knife point does more damage than an unsharpened knife point.

This type of Class B tubing engraves well, but cuts very little depth and tends to cause scorch around the laser cut.

How You Use Your Laser Tube Can Affect Its Lifespan.

Another consideration is how you use the laser tube.

If you're mostly cutting thicker material, you'll notice power loss pretty quickly because you're running the tube close to the maximum current recommended. The only way to get around this is to reduce the cutting speed, but that quickly becomes unfeasible.

If you're only doing engraving, you can lose 50% of your power before it starts affecting your fabrication.

Super Speed Tube

Running the tubes at too high a % power output can cause the tubes to be overdriven. This is basically the process by which the gas in the laser tube breaks down, reducing the maximum power output of the tube. Yellowing of the cathode may indicate that the tube has been overloaded.