Whether it's a large acrylic product run or an order requiring the highest level of customization, laser technology is here to stay in the acrylic industry. Laser engraver that consistently provide the smoothest cuts and superior design metrics are being used to cut, engrave and mark acrylic! Get your favorite brands and styles of laser engraving machines at HTPOW.

Gone are the days when the acrylic industry used traditional processing systems to create signs, gift items and other promotional materials. Ortur Laser Master 3 is now successful with its high flexibility and versatile options; smooth polished cutting edge without rework; force-free and contact-free machining means; freely selectable contours; single-step laser cutting and engraving process; There are more. With smart and newer open software structures and optical recognition systems in place, laser technology and tools are sure to play a role in the acrylic industry, and how!

Laser Advantages in the Acrylic Industry

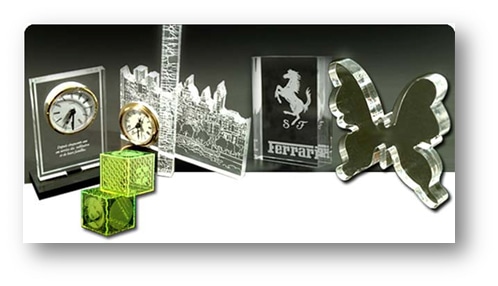

A simple announcement is just one small step in the successful launch of any product. There is a lot going on in presenting a product in the right way and getting potential buyers to come and select and buy it. This is where the display stands and presenters made of acrylic, masterfully treated with the latest Ortur Laser Master 3 laser cutting system, come in handy for their quality and elegance. These acrylic giveaways attract the eye and provide a glimpse into the laser cutting, marking and engraving capabilities of a laser-based system, which goes a long way toward convincing customers that the product being sold is of the highest quality.

Laser and Acrylic - Combination

The Ortur laser offers numerous advantages for processing acrylic compared to other technologies. All processed products require minimal finishing. Any other form of cutting is bound to produce sharp edges that require polishing, deburring and milling. This can be avoided entirely by using a laser. Saving costs, but more importantly, time, laser cuts in acrylic tend to be very clean and require no finishing.

Lasers also have the added advantage of less processing. Reduce the risk of personal damage and injury; and etch finer lines on acrylic products. As we all know, each acrylic material and thickness requires specialized tools. This can be avoided by using a laser for cutting and finishing. While alternative methods require jigs and associated materials, in addition to being bulky, they cause time overlap and potential damage to the acrylic material; with laser cutting, a vacuum cup can be used to hold the material in place

Generate Better Acrylic Sales

With the use of lasers in acrylic, the applications of this material increased a lot. An investment in deft craftsmanship and well-designed tooling led to a wider acceptance of acrylic. A special coating is also available which makes the acrylic completely flame retardant and less likely to burn. This in turn provides higher volumes and better economies of scale, thereby bringing the acrylic industry closer to various verticals. Laser-acrylic combinations allow for better aesthetics and premium presentation. Since laser cutting is precise, contact-free and clean, it brings better results than traditional methods.

The Future of Acrylic with Laser-Driven Technology

The widespread acceptance of acrylic has led to many everyday applications of this material. Once considered a material only for spacecraft and astronauts, the use of lasers has now significantly reduced the cost of using them, making their application and acceptance easier. The future of acrylic is entirely laser-driven, and for good reason. Lasers bring out the best in precision, high quality and fine cuts, why should observers of the acrylic industry look elsewhere!